Hyundai Elantra (CN7): Clutch System / Clutch Cover And Disc

Repair procedures

| Removal |

| 1. | Remove the manual transaxle assembly. (Refer to Manual Transaxle System - "Manual Transaxle") |

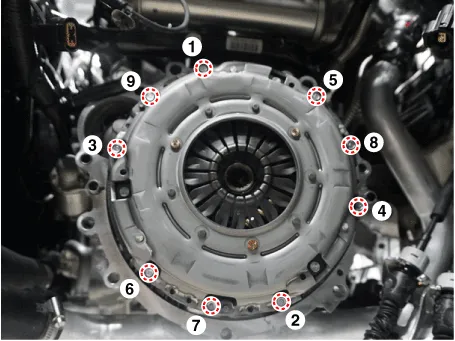

| 2. | Remove the clutch cover assembly after loosening the bolts.

[Gasoline 1.6 MPI / Gasoline 1.6 T-GDI]

[Gasoline 2.0 MPI]

|

| Inspection |

| 1. | Inspect diaphragm spring wear which is in contact with a concentric slave cylinder bearing. |

| 2. | Check the clutch cover and disc surface for wear or cracks. |

| 3. | Check the clutch disc facing for slipping or oil marks. |

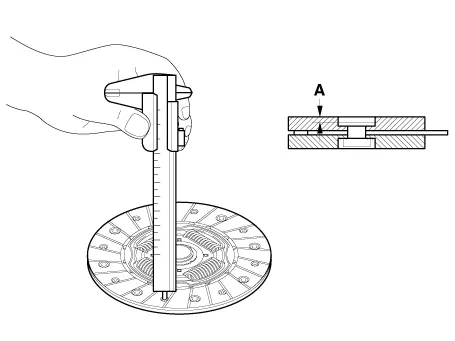

| 4. | Measure the depth from a clutch facing surface to a rivet. If the measured value is less than the specification below, replace it.

|

| Installation |

|

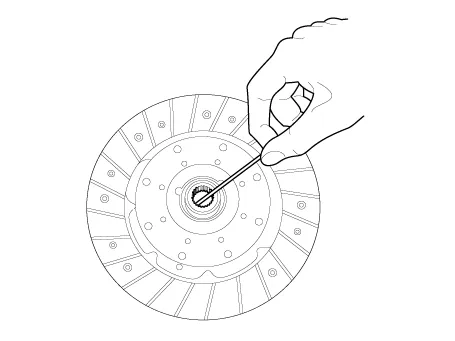

| 1. | Apply grease on a disc spline part and transaxle input shaft spline part as required.

|

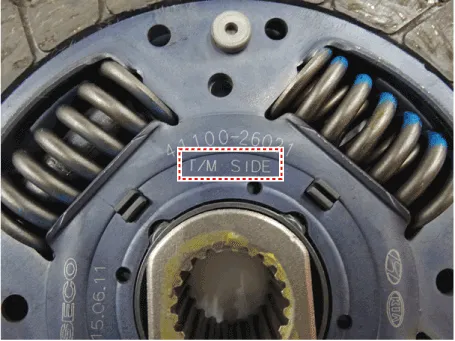

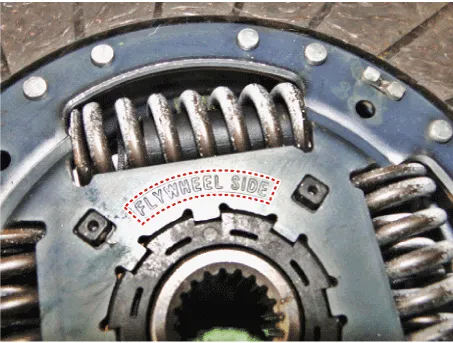

| 2. | Before installing the clutch disc, check the “TM SIDE” and “FLYWHEEL SIDE” marked on the clutch disc, and install it with the clutch cover using a special tool (09411-1P000).

|

| 3. | Install the clutch disc and the cover with SST (A: 09411-1P000).

|

| 4. | Install the clutch cover mounting bolts.

|

| 5. | Remove the clutch disc guide SST (No.: 09411-1P000).

|

| 6. | Install the transaxle assembly. (Refer to Manual Transaxle System - "Manual Transaxle") |

Description and operation Description– Clutch operation is detected through clutch switch signal. This signal enables ECM to cope with instant change of load condition.

Other information:

Hyundai Elantra (CN7) 2021-2026 Service Manual: Auto Defogging Sensor

Description DescriptionThe auto defogging sensor is installed on the front window glass. The sensor judges and sends signal if moisture occurs to blow out wind for defogging. The air conditioner control module receives signal from the sensor and restrains moisture and eliminate defog by controlling the intake actuator, A/C, auto defogging actuat

Hyundai Elantra (CN7) 2021-2026 Service Manual: Description and operation

DescriptionRear Corner Radar is a system that measures the relative speed and distance from the following vehicles by using two electromagnetic wave radar sensors attached to the rear bumper, and detects any vehicle within the blind spot zone and gives off alarm.

Categories

- Manuals Home

- Hyundai Elantra Owners Manual

- Hyundai Elantra Service Manual

- Rear Seats

- Body Electrical System

- Drive Mode

- New on site

- Most important about car