Hyundai Elantra (CN7): Engine Mechanical System / Repair procedures

| Compession Pressure Inspection |

|

| 1. | Start the engine and turn the coolant temperature to 80 - 95 °C and stop. |

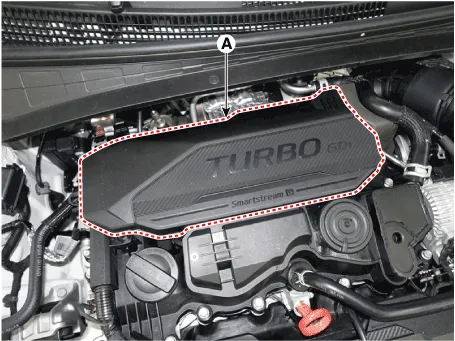

| 2. | Remove the engine cover (A).

|

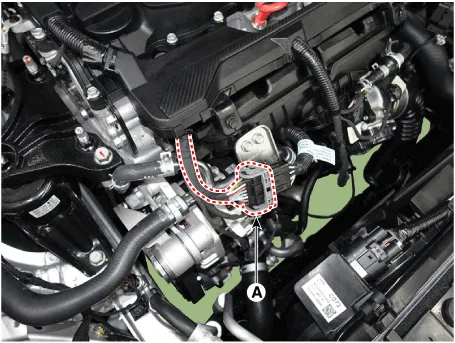

| 3. | Disconnect the injector connector (A).

|

| 4. | Remove the ignition coils. (Refer to Engine Electical System - "Ignition Coil") |

| 5. | Remove spark plugs. (Refer to Engine Electrical System - "Spark Plug") |

| 6. | Check the cylinder compression pressure.

|

| 7. | Install the spark plugs. (Refer to Engine Electrical System - "Spark Plug") |

| 8. | Install the ignition coil. (Refer to Engine Electical System - "Ignition Coil") |

| 9. | Connect the injector connector (A).

|

| 10. | Some DTCs may exist after the inspection test and may need to be manually cleared with diagnostic tool. |

| 11. | Install the engine cover. (Refer to Engine and Transaxle Assembly - "Engine Cover") |

Specifications Description Specifications Limit General TypeIn-line, DOHC  Number of cylinders4  Bore75.

Troubleshooting Symptom Suspect area Remedy Engine misfire with abnormal internal lower engine noises.

Other information:

Hyundai Elantra (CN7) 2021-2026 Service Manual: Head Lamp Leveling Device

Components and components location Component Location1. Head lamp leveling actuator2. Head lamp leveling switch Head Lamp Leveling Switch Schematic diagrams Schematic Diagrams Repair procedures Replacement1.Disconnect the negative (-) battery terminal.

Hyundai Elantra (CN7) 2021-2026 Service Manual: Wireless Power Charging Unit

Components and positions Components Circuit diagram Circuit Diagram Repair procedures Removal • Handling wireless charging system parts by wet hands may cause electric shock. 1.Disconnect the negative (-) battery terminal.

Categories

- Manuals Home

- Hyundai Elantra Owners Manual

- Hyundai Elantra Service Manual

- Recommended Cold Tire Inflation Pressures

- Front Radar Unit

- General Tightening Torque Table. General information

- New on site

- Most important about car