Hyundai Elantra (CN7): Brake System / Brake bleeding procedures

| Brake System Bleeding |

|

| 1. | Make sure the brake fluid in the reservoir is at the MAX (upper) level line. |

| 2. | Have someone slowly pump the brake pedal several times, and then apply pressure. |

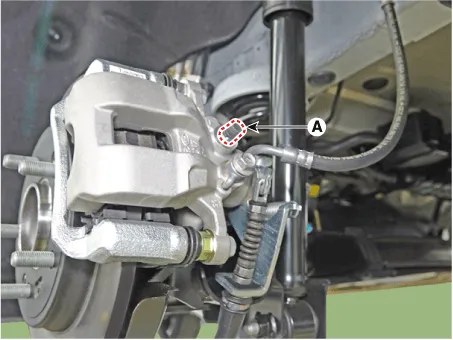

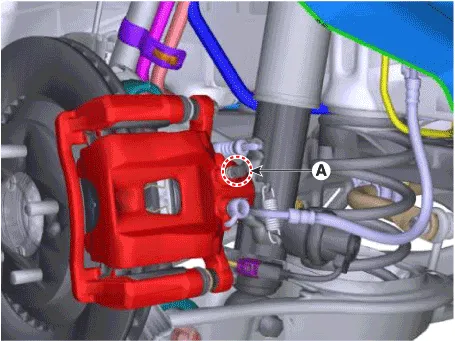

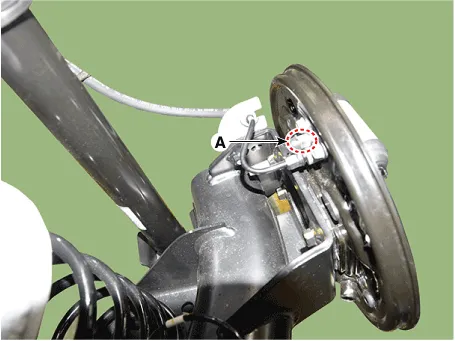

| 3. | Loosen the right-rear brake bleed screw (A) to allow air to escape from the system. Then tighten the bleed screw securely. [Front]

[Rear torsion beam parking cable type]

[Rear torsion beam EPB type]

[Rear multi link parking cable type]

[Rear multi link EPB type]

[Rear drum brake type]

|

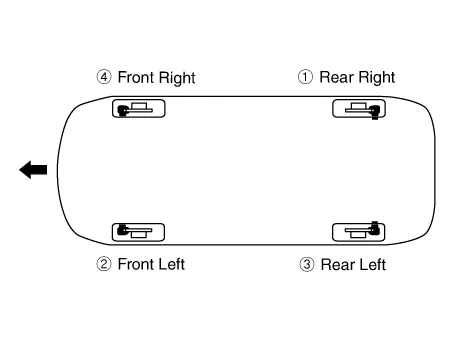

| 4. | Repeat the procedure for wheel in the sequence shown below until air bubbles no longer appear in the fluid. |

| 5. | Follow the sequence as shown below.

|

| 6. | Refill the master cylinder reservoir to MAX (upper) level line. |

| 1. | Remove the reservoir cap and fill the brake reservoir with brake fluid.

|

| 2. | Connect a clear plastic tube to the wheel cylinder bleeder plug and insert the other end of the tube into a half filled clear plastic bottle. |

| 3. | Connect the diagnostic tool to the data link connector located underneath the dash panel. |

| 4. | Select and operate according to the instructions on the diagnostic tool screen.

|

| 5. | Have someone slowly pump the brake pedal several times, and then apply pressure. |

| 6. | Pump the brake pedal several times, and then loosen the bleeder screw until fluid starts to run out without bubbles. Then close the bleeder screw (A). [Front]

[Rear torsion beam parking cable type]

[Rear torsion beam EPB type]

[Rear multi link parking cable type]

[Rear multi link EPB type]

[Rear drum brake type]

|

| 7. | Repeat the procedure for wheel in the sequence shown below until air bubbles no longer appear in the fluid. |

| 8. | Follow the sequence as shown below.

|

| 9. | Refill the master cylinder reservoir to MAX (upper) level line. |

Special Service Tools Tool (Number and Name) Illustration Use 09581-11000Piston expanderSpreading the front disc brake piston.

Other information:

Hyundai Elantra (CN7) 2021-2026 Service Manual: Wireless Charging Lamp

Components and positions Components Repair procedures Removal • Handling wireless charging system parts by wet hands may cause electric shock. 1.Disconnect the negative (-) battery terminal.2.Remove the floor console upper cover assembly.

Hyundai Elantra (CN7) 2021-2026 Service Manual: Desctiprion and operation

DescriptionADAS_PRK is a unit that controls the functions required for ADAS parking. If the ADAS_PRK is applied, the parking distance warning function is also controlled by the ADAS_PRK.System FunctionParking Collision-Avoidance Assist (PCA)PCA is a parking safety system that assists in collision warning and emergency braking in the event of a coll

Categories

- Manuals Home

- Hyundai Elantra Owners Manual

- Hyundai Elantra Service Manual

- Rear Seats

- Recommended Lubricants and Capacities

- Towing

- New on site

- Most important about car