Hyundai Elantra (CN7): Cylinder Block / Cylinder Block

Hyundai Elantra (CN7) 2021-2026 Service Manual / Engine Mechanical System / Cylinder Block / Cylinder Block

Repair procedures

| Disassembly |

|

|

| 1. | Remove the crankshaft. (Refer to Cylinder Block - "Crankshaft") |

| 2. | Remove the water jacket insert. (Refer to Cylinder Block - "Water Jacket Insert") |

| 3. | Remove the knock sensor. (Refer to Engine Control / Fuel System - "Knock Sensor (KS)") |

| 4. | Remove the crankshaft position sensor (CKPS). (Refer to Engine Control / Fuel System - "Crankshaft Position Sensor (CKPS)") |

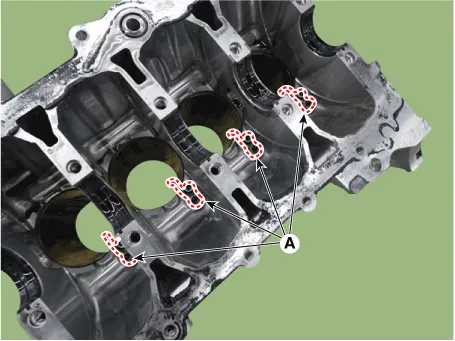

| 5. | Remove the piston cooling oil jets (A).

|

| Inspection |

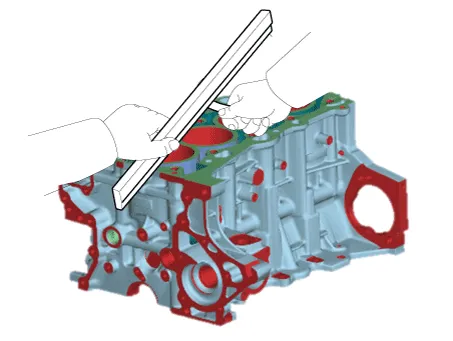

| 1. | Using a gasket scraper, remove all the gasket material from the top surface of the cylinder block. |

| 2. | Using a soft brush and solvent, thoroughly clean the cylinder block. |

| 3. | Inspect the top surface of cylinder block for flatness. Using a precision straight edge and feeler gauge, measure the surface contacting the cylinder head gasket for warpage.

|

| 4. | Visually check for scratches on the inside surface of the cylinder bore and replace the cylinder block if any noticeable scratch is detected. If deep scratchs are present, replace the cylinder block. |

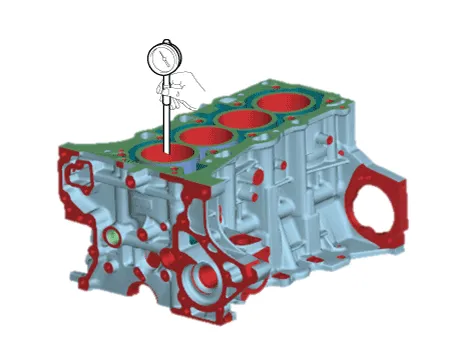

| 5. | Using the cylinder bore gauge, measure the cylinder bore’s inner diameter to the axial and axial perpendicular directions.

|

| Reassembly |

|

| 1. | Install the piston cooling oil jets (A).

|

| 2. | Install the crankshaft. (Refer to Cylinder Block - "Crankshaft") |

| 3. | Check the crankshaft end play. (Refer to Cylinder Block - "Crankshaft") |

| 4. | Disconnect the lower crankcase and check crankshaft bearing oil clearance. (Refer to Cylinder Block - "Crankshaft") |

| 5. | Install the piston and connecting rod assembly. (Refer to Cylinder Block - "Piston and Connecting Rod") |

| 6. | Check the connecting rod bearing cap oil clearance. (Refer to Cylinder Block - "Piston and Connecting Rod") |

| 7. | Check the connecting rod end play. (Refer to Cylinder Block - "Piston and Connecting Rod") |

| 8. | Assemble the other parts in the reverse order of disassembly.

|

Repair procedures Disassembly • Use fender covers to avoid damaging painted surfaces.• To avoid damage, unplug the wiring connectors carefully while holding the connector portion.

Other information:

Hyundai Elantra (CN7) 2021-2026 Service Manual: Specification

S

Hyundai Elantra (CN7) 2021-2026 Service Manual: Heater Control Unit

Components and components location Component Location1. Heater control unitComponents[Connector A] Pin No Function Pin No Function 1Mode control actuator (Feedback)21Mode control actuator (Vent)2Intake actuator (Feedback)22Mode control actu

Categories

- Manuals Home

- Hyundai Elantra Owners Manual

- Hyundai Elantra Service Manual

- Body Electrical System

- Engine Mechanical System

- Maintenance

- New on site

- Most important about car

Copyright © 2026 www.helantra7.com - 0.0127