Hyundai Elantra (CN7): Seat Electrical / Power Seat Motor

Hyundai Elantra (CN7) 2021-2026 Service Manual / Body Electrical System / Seat Electrical / Power Seat Motor

Components and components location

| Component Location |

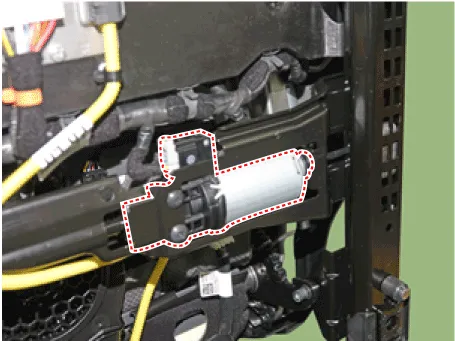

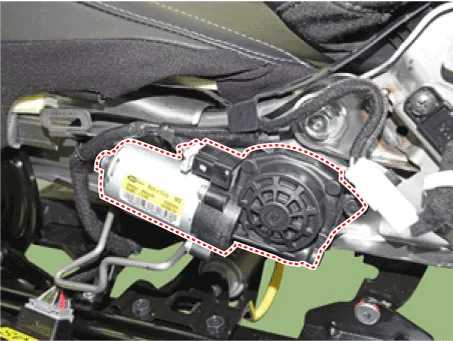

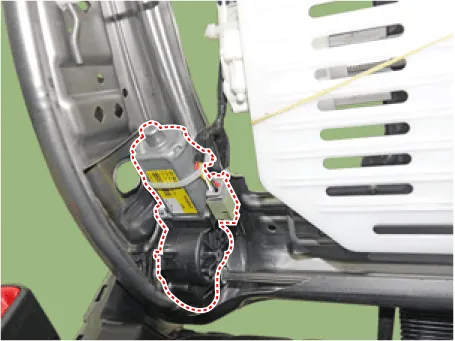

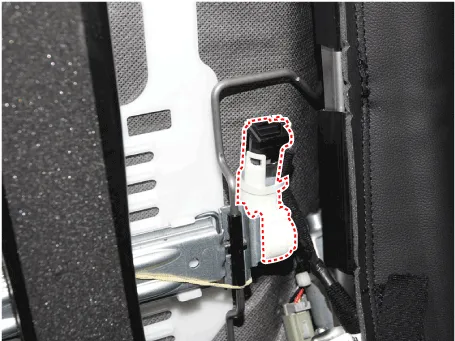

| 1. Lumber support motor 2. Reclining motor 3. Front height motor 4. Slide motor | 5. Rear height motor 6. Reclining limit switch 7. Lumber support switch 8. Seat switch |

Repair procedures

| Inspection |

Power Seat Motor

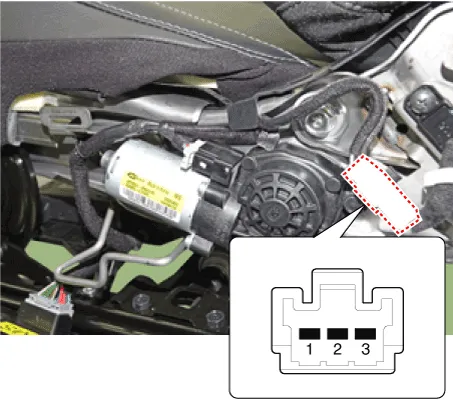

| 1. | Disconnect the connectors for each motor. [Slide Motor]

[Rear Height Motor]

[Front Height Motor]

[Reclining Motor]

[Lumbar Support Motor]

|

| 2. | With the battery connected directly to the motor terminals, check if the motors run smoothly. |

| 3. | Reverse the connections and check that the motor turns in reverse. |

| 4. | If there is an abnormality, replace the motors. |

[Reclining Motor Limit Switch]

|

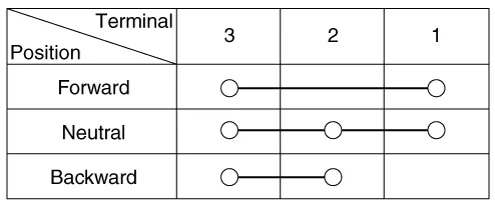

| 1. | Disconnect the limit switch and operate the limit switch. |

| 2. | Check for continuity between the terminals. |

| 3. | Make sure that the seat operation is normal in the reverse after the maximum operation. |

| 4. | If there is an abnormality, replace the limit switch.

|

| Remove |

Front Seat

| 1. | Disconnect the battery terminals. |

| 2. | Remove the front seat assembly. (Refer to Body - "Front Seat Assembly") |

Repair procedures Removal1.Disconnect the negative (-) battery terminal.2.Remove the front seat outer shield cover.(Refer to Body - "Front Seat Outer Shield Cover")3.

Other information:

Hyundai Elantra (CN7) 2021-2026 Service Manual: Specifications

SpecificationAir Conditioner Item Specification CompressorTypeGamma 1.6 MPI, Gasoline 2.0 NU MPI, Gasoline 1.6 T-GDI : 6HVx14Gasoline 1.6 MPI : 6HVe14Oil type & CapacityFD46XG (IDEMITSU) 100 ± 10 g Pulley type6PK-TYPEDisplacement145 cc/revExpansion valveTypeBlock type RefrigerantTypeR - 134

Hyundai Elantra (CN7) 2021-2026 Service Manual: Components and components location

C

Categories

- Manuals Home

- Hyundai Elantra Owners Manual

- Hyundai Elantra Service Manual

- Components and components location

- Clutch System

- Recommended Lubricants and Capacities

- New on site

- Most important about car

Copyright © 2026 www.helantra7.com - 0.0135