Hyundai Elantra (CN7): Windshield Wiper/Washer / Front Wiper Motor

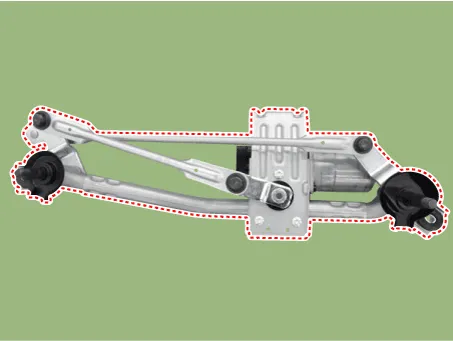

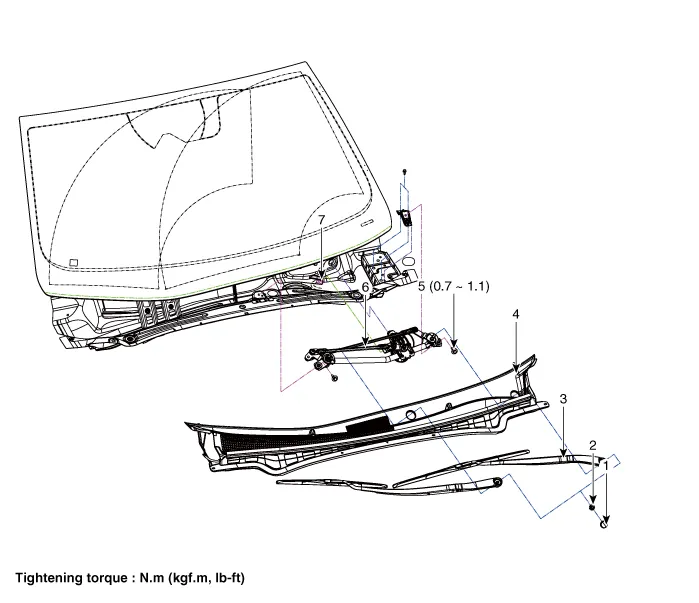

Components and components location

| Component Location |

| 1. Cap 2. Nut 3. Wiper arm & blade 4. Cowl top cover | 5. Bolt 6. Wiper motor & linkage assembly 7. Wiper motor connector |

Repair procedures

| Removal |

| 1. | Disconnect the negative (-) battery terminal. |

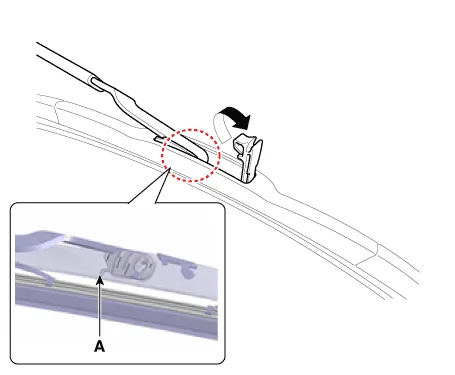

| 2. | If necessary, release the wiper blade fixing clip by pulling up and remove the wiper blade from the inside radius of wiper arm.

|

| 3. | Remove the cowl top cover. (Refer to Body - "Cowl Top Cover") |

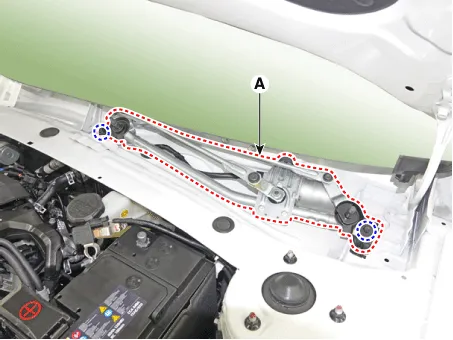

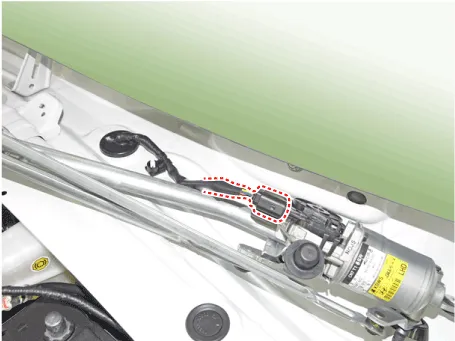

| 4. | Remove the windshield wiper motor and linkage assembly (A) after removing 2 bolts.

|

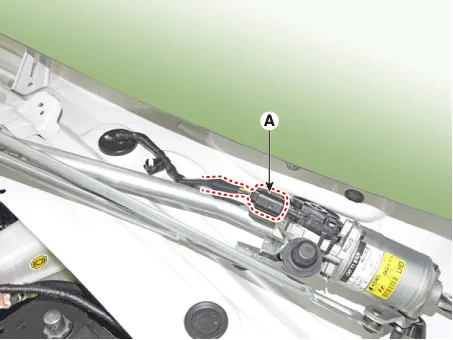

| 5. | Disconnect the wiper motor connector (A) from the wiper motor & linkage assembly.

|

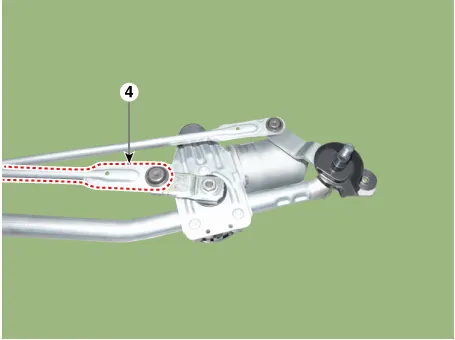

| 6. | Hold the wiper motor crank arm and remove the upper linkage (A) from the wiper motor crank arm.

|

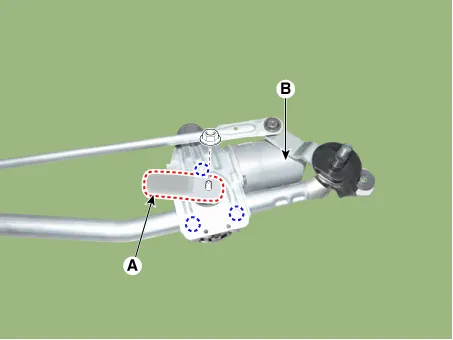

| 7. | Loosen the mounting nut, screws and remove the crank arm (A) and wiper motor (B).

|

| Installation |

| 1. | Install the wiper motor and linkage assembly and then connect the wiper motor connector.

|

| 2. | Install the crank arm.

|

| 3. | Install the cowl top cover. |

| 4. | Install the windshield wiper arm and blade.

|

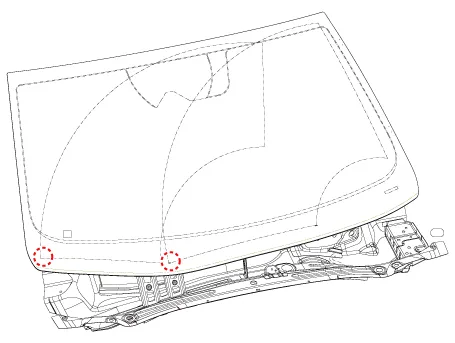

| 5. | Install the wiper arm and blade to the specified position.

|

| Inspection |

| 1. | Remove the connector from the wiper motor.

|

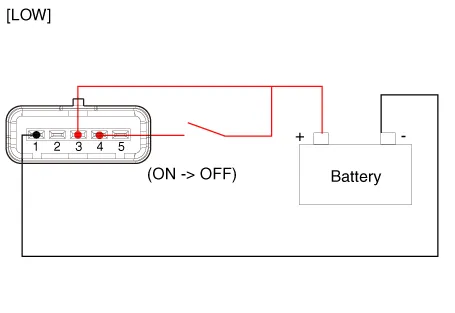

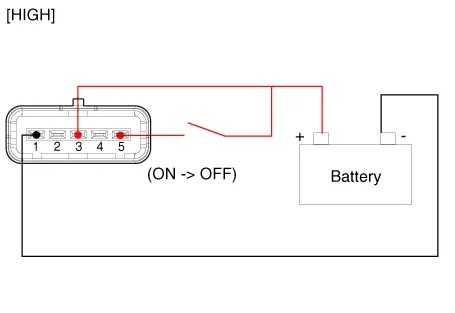

| 2. | Attach the positive (+) lead from the battery to terminal 3 and the negative (-) lead to terminal 5.

|

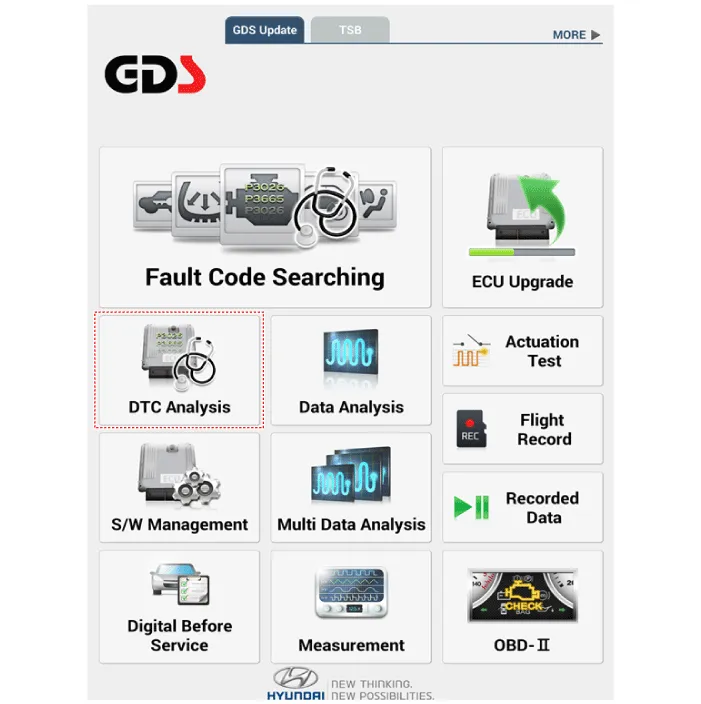

| 1. | In the body electrical system, failure can be quickly diagnosed by using the vehicle diagnostic system (Diagnostic tool). The diagnostic system (Diagnostic tool) provides the following information.

|

| 2. | If diagnose the vehicle by Diagnostic tool, select "DTC Analysis" and "Vehicle".

|

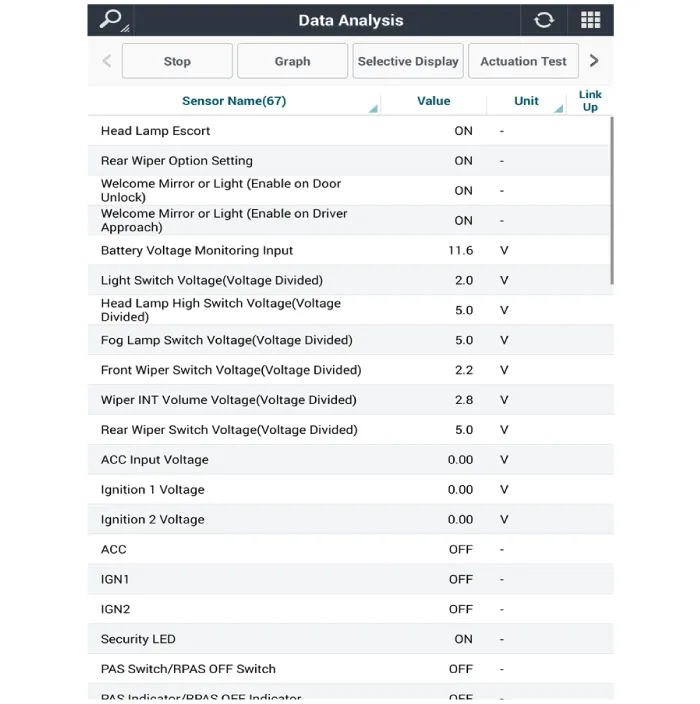

| 3. | Select the 'Data Analysis'.

|

| 4. | Select the 'IBU_BCM' to search the current state of the input/output data.

|

Repair procedures Removal1.Disconnect the negative (-) battery terminal.2.If it is necessary to remove multifunction switch assembly, remove the steering wheel.

Repair procedures InspectionFront Washer Motor1.With the washer motor connected to the reservoir tank, fill the reservoir tank with water. • Before filling the reservoir tank with water, check the filter for foreign material or contamination.

Other information:

Hyundai Elantra (CN7) 2021-2026 Service Manual: Mood Lamp

Repair procedures RemovalMood lamp unit1.Disconnect the negative (-) battery terminal.2.Remove the main crash pad assembly.(Refer to Body - "Main Crash Pad Assembly")3.Loosen the mounting screws and remove the main crash pad air duct (A).4.Loosen the mounting screws and remove the mood lamp unit (A).

Hyundai Elantra (CN7) 2021-2026 Service Manual: General safety information and caution

General Safety Information and Caution1.Be careful when driving the vehicle using the smart cruise control system as follows.(1)On curves or inclines/declines• The smart cruise control system may have limits to detect distance to the vehicle ahead due to road and traffic conditions.

Categories

- Manuals Home

- Hyundai Elantra Owners Manual

- Hyundai Elantra Service Manual

- Recommended Cold Tire Inflation Pressures

- General Tightening Torque Table. General information

- Body Electrical System

- New on site

- Most important about car