Hyundai Elantra (CN7): Air Conditioning System / Refrigerant Line

Components and components location

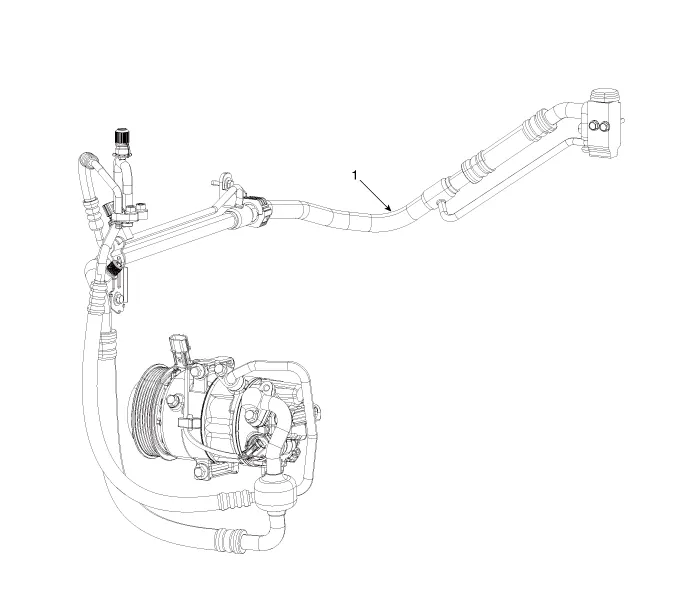

| Components Location |

| 1. Refrigerant Pipe Assembly |

Repair procedures

| Replacement |

| 1. | If the compressor is marginally operable, run the engine at idle speed, and let the air conditioning work for a few minutes, then shut the engine off. |

| 2. | Disconnect the negative (-) battery terminal. |

| 3. | Recover the refrigerant with a recovery / charging station. |

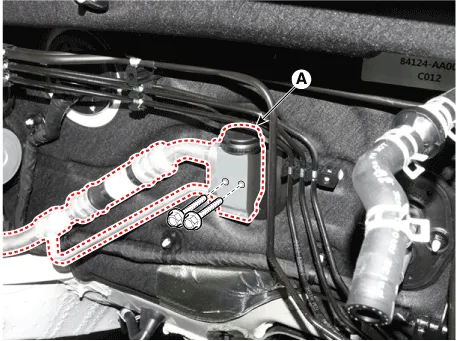

| 4. | Remove the bolts and the expansion valve (A) from the evaporator core.

|

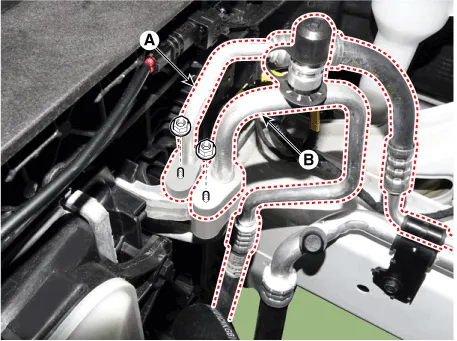

| 5. | Loosen the mounting nuts, and then disconnect the discharge line (B) and liquid line (A) from the condenser.

|

| 6. | Disconnect the A/C pressure transducer connector (A).

|

| 7. | Remove the engine room under cover. (Refer to Engine Mechanical System - "Engine Room Under Cover") |

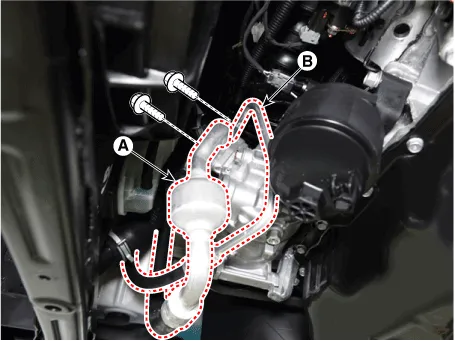

| 8. | Remove the bolts, then disconnect the suction line (A) and discharge line (B) from the compressor.

|

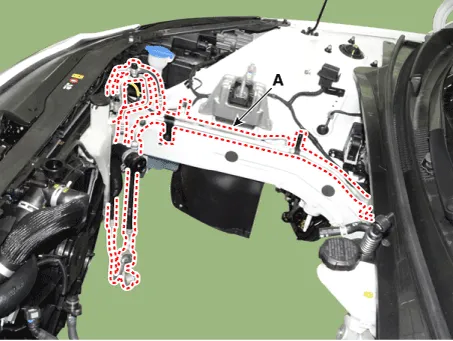

| 9. | Remove the refrigerant line assembly (A) to the upper of engine room.

|

| 10. | To install, reverse the removal procedure.

|

Repair procedures Oil Specification1.The HFC-134a system requires synthetic (PAG) compressor oil whereas the R-12 system requires mineral compressor oil.

Description and operation DescriptionThe compressor is the power unit of the A/C system.It is located on the side of engine block and driven by a V-belt of the engine.

Other information:

Hyundai Elantra (CN7) 2021-2026 Service Manual: Rear Combination Lamp

Repair procedures RemovalOutside Combination Lamp1.Disconnect the negative (-) battery terminal.2.Remove the combination lamp cover (A).3.Disconnect the rear combination lamp connector (A).4.Loosen the mounting nuts and remove the rear conbination lamp (A).

Hyundai Elantra (CN7) 2021-2026 Service Manual: Auto Defoging Actuator

Description and operation DescriptionThe auto defogging sensor is installed on front window glass. The sensor judges and sends signal if moisture occurs to blow out wind for defogging. The air conditioner control module receives a signal from the sensor and restrains moisture and eliminates defog by the intake actuator, A/C, auto defogging actua

Categories

- Manuals Home

- Hyundai Elantra Owners Manual

- Hyundai Elantra Service Manual

- Recommended Cold Tire Inflation Pressures

- Clutch System

- Front Radar Unit

- New on site

- Most important about car