Hyundai Elantra (CN7): Air Conditioning System / Compressor

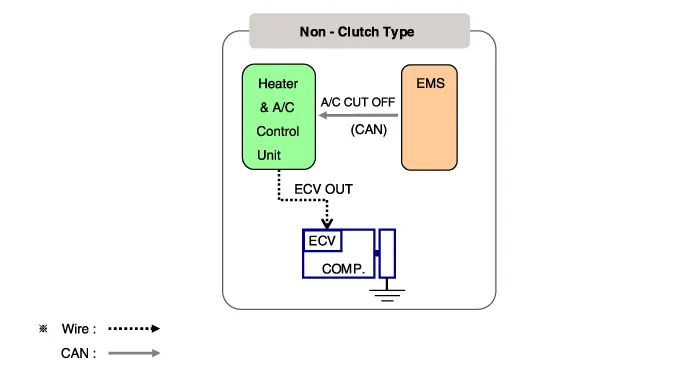

Description and operation

| Description |

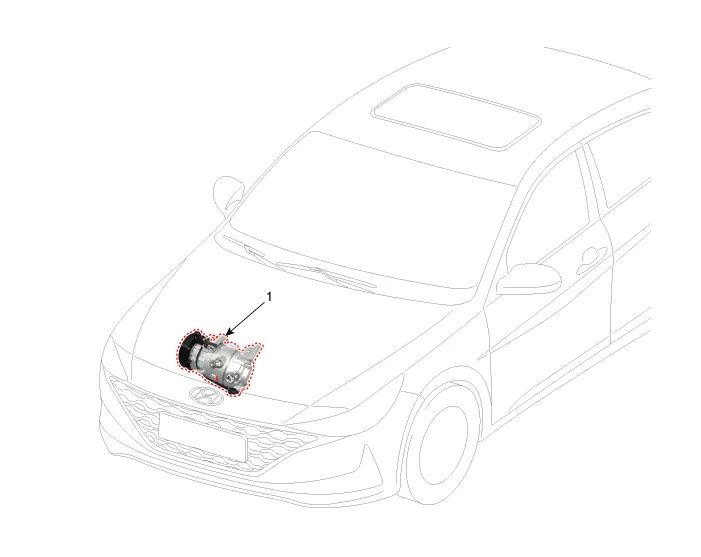

Components and components location

| Components Location |

| 1. Compressor |

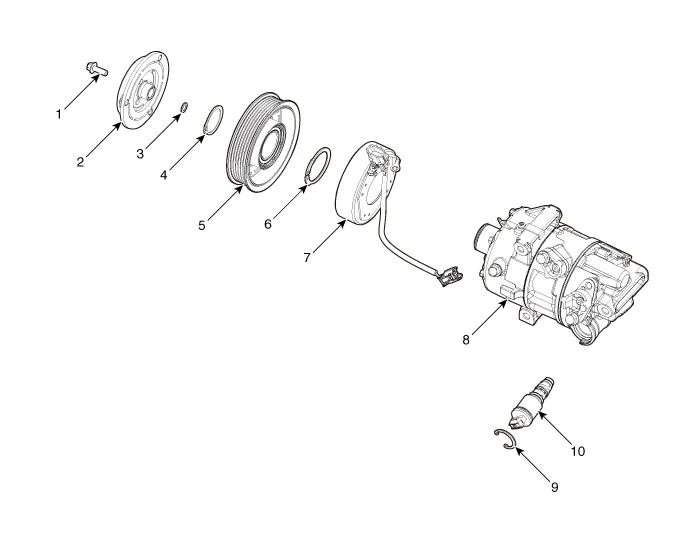

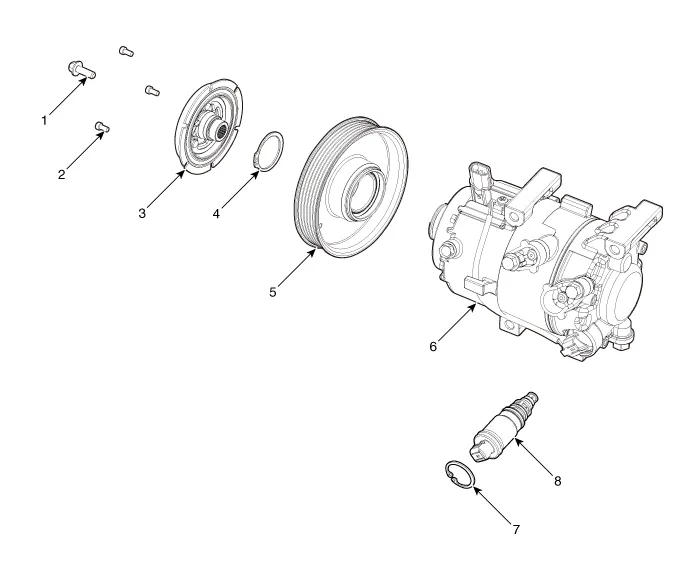

| Components |

| 1. Clutch bolt 2. Disc & Hub assembly 3. Air gap spacer 4. Retainer (A) 5. Pulley 6. Retainer (B) | 7. Clutch magnetic coil 8. Compressor 9. Electric Control Valve(ECV) Snap ring 10. Electric Control Valve (ECV) |

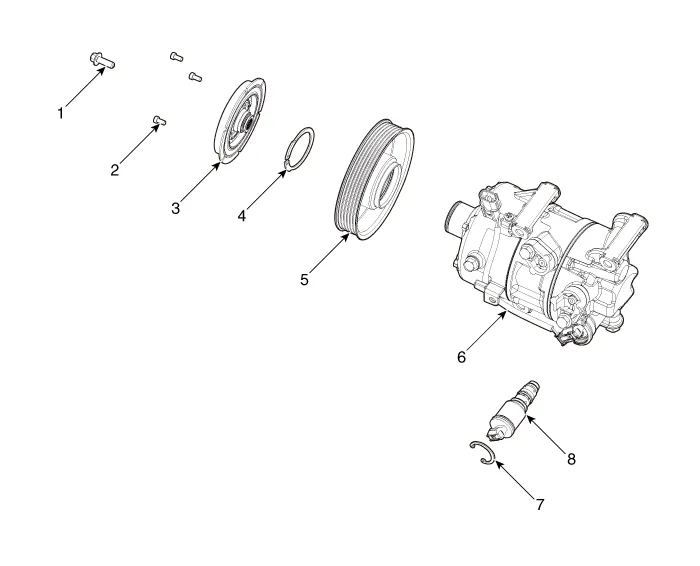

| 1. Clutch bolt 2. Limiter bolt 3. Disc & Hub assembly 4. Snap ring | 5. Pulley 6. Compressor 7. Electric Control Valve(ECV) Snap ring 8. Electric Control Valve (ECV) |

| 1. Clutch bolt 2. Limiter bolt 3. Disc & Hub assembly 4. Snap ring | 5. Pulley 6. Compressor 7. Electric Control Valve(ECV) Snap ring 8. Electric Control Valve (ECV) |

Repair procedures

| Removal |

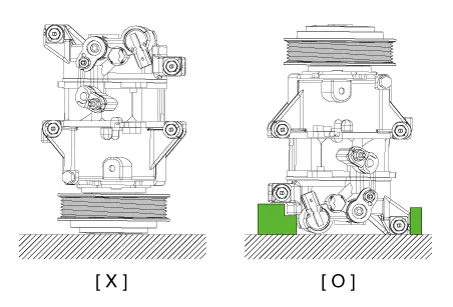

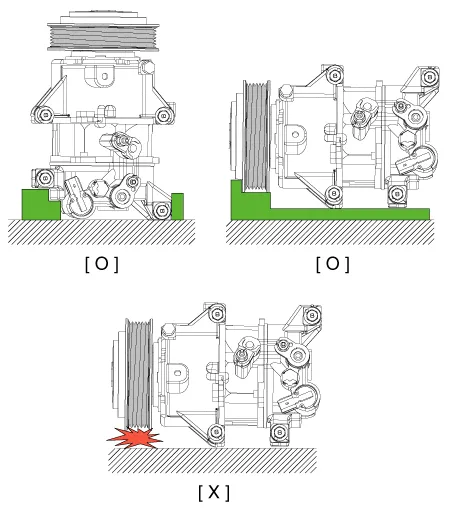

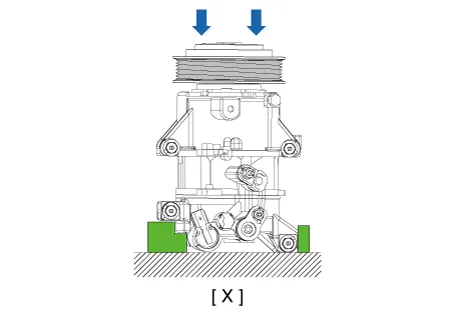

Precautions for using the plastic pulley

|

| 1. | If the compressor is marginally operable, run the engine at idle speed, and let the air conditioning work for a few minutes, then shut the engine off. |

| 2. | Disconnect the negative (-) battery terminal. |

| 3. | Recover the refrigerant with a recovery / charging station. |

| 4. | Remove the engine room under cover. (Refer to Engine Mechanical System - "Engine Room Cover") |

| 5. | Remove the front wheel guard. (Refer to Body - "Front Wheel Guard") |

| 6. | Loosen the drive belt. (Refer to Engine Mechanical System - "Drive Belt") |

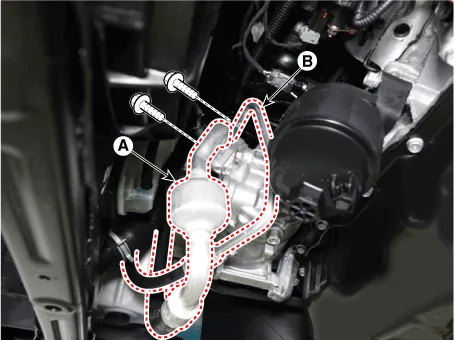

| 7. | Remove the bolts, then disconnect the suction line (A) and discharge line (B) from the compressor.

|

| 8. | Disconnect the compressor switch connector (A).

|

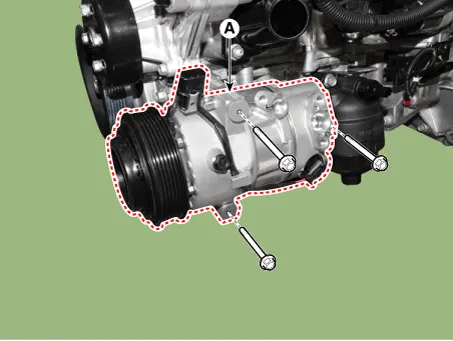

| 9. | Remove the compressor (A) by loosening the mounting bolts.

|

| Installation |

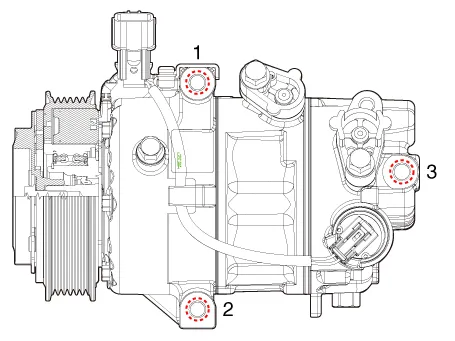

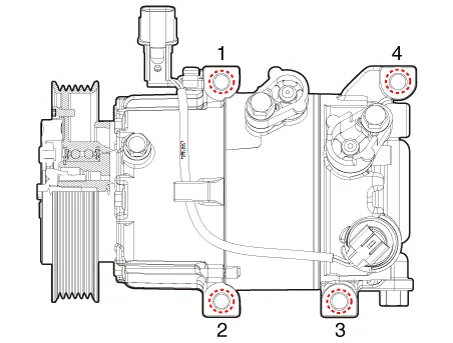

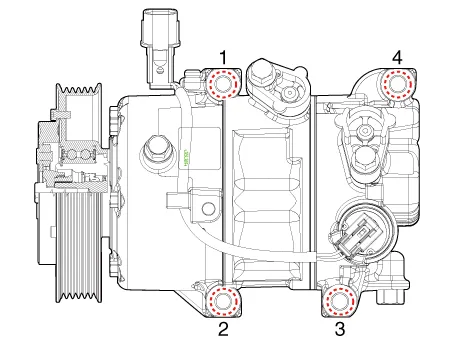

| 1. | Make sure the compressor mounting bolt with the correct length is screwed in. Tighten the mounting bolts with the specified tightening order.

[Gasoline 1.6 MPI]

[Gasoline 1.6 T-GDI, Gasoline 2.0 MPI NU]

[Gamma 1.6 MPI]

|

| 2. | To install, reverse the removal procedure.

|

| Inspection |

| 1. | Check the plated parts of the limiter & hub assembly for color changes, peeling or other damage. If there is damage, replace the assembly. |

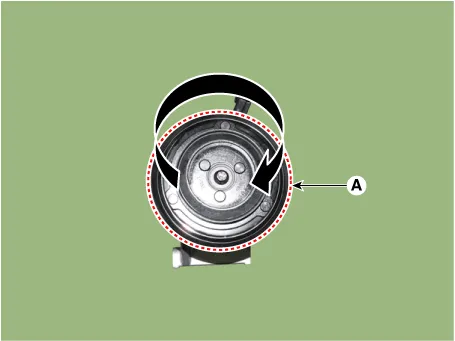

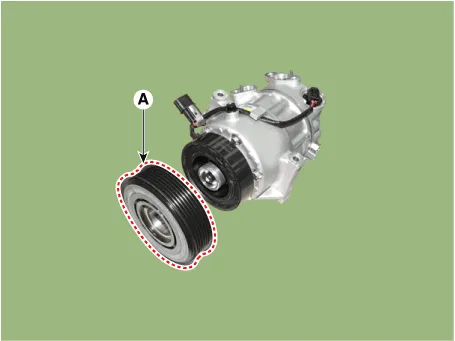

| 2. | Check the pulley (A) bearing play and drag by rotating the pulley by hand. Replace the pulley with a new one if it is noisy or has excessive play / drag.

|

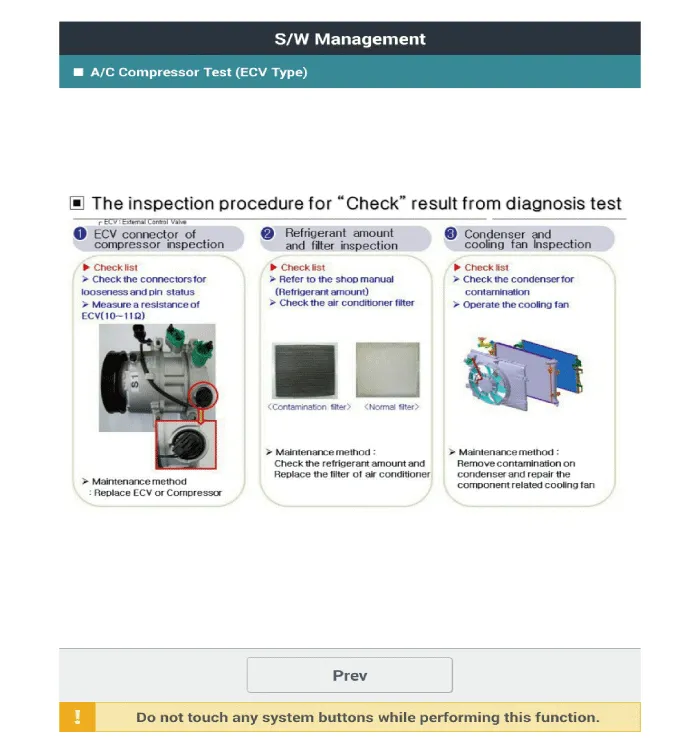

| External Control Valve Compressor Inspection (Diagnostic tool) |

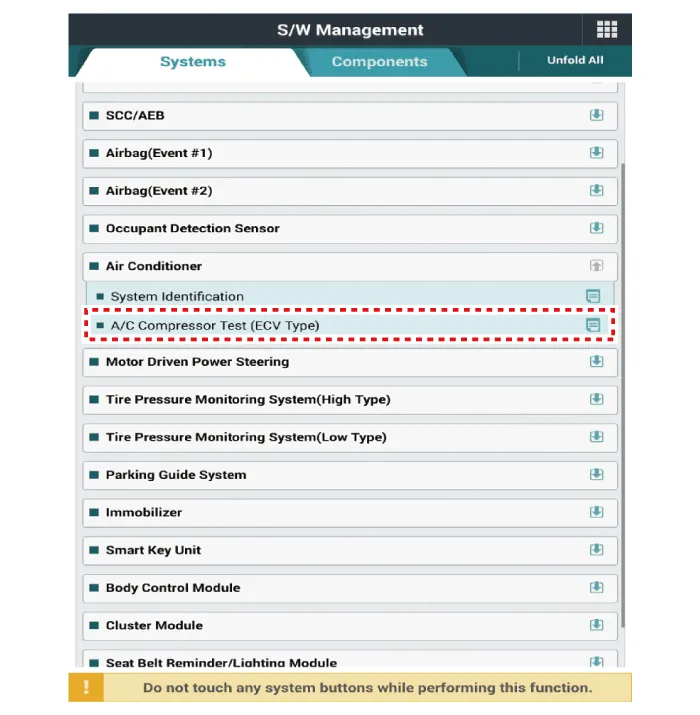

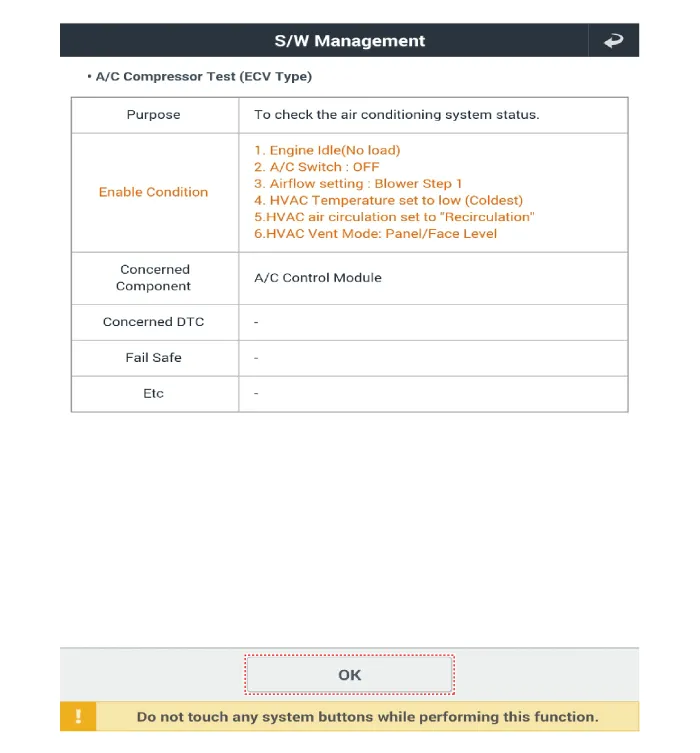

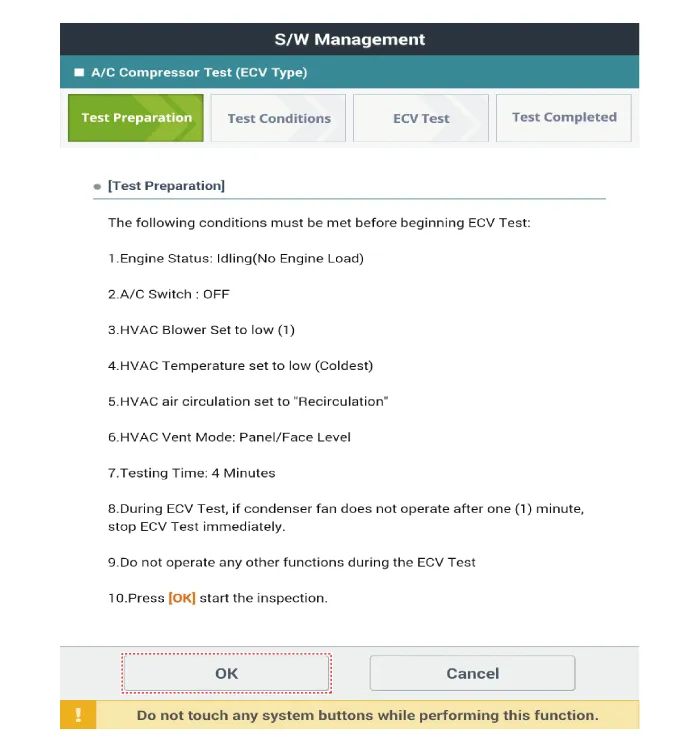

| 1. | Connect diagnostic tool to the vehicle and select 'Aircon Compressor Test(ECV type)' [ECV1]

|

| 2. | Make the vehicle ready as the diagnostic tool instruction on the monitor. (Turn off A/C 'switch' only)

|

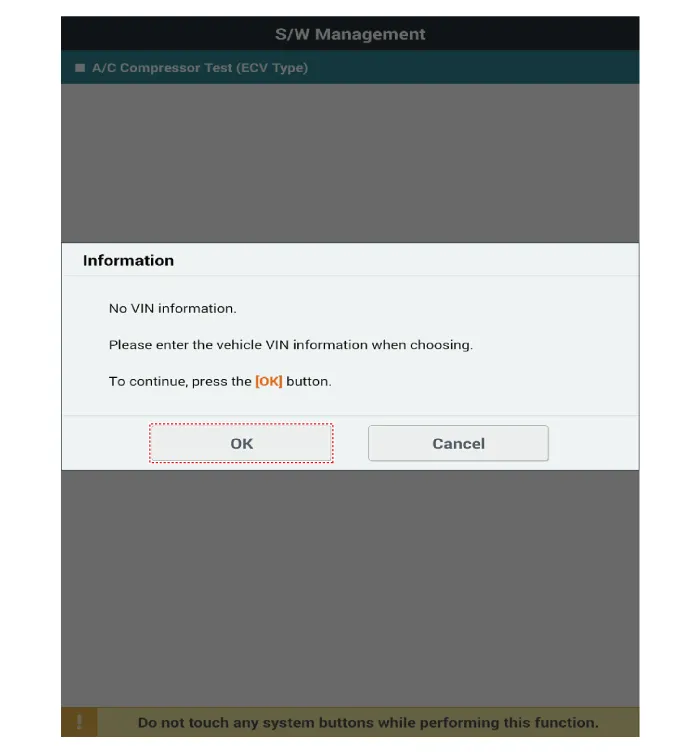

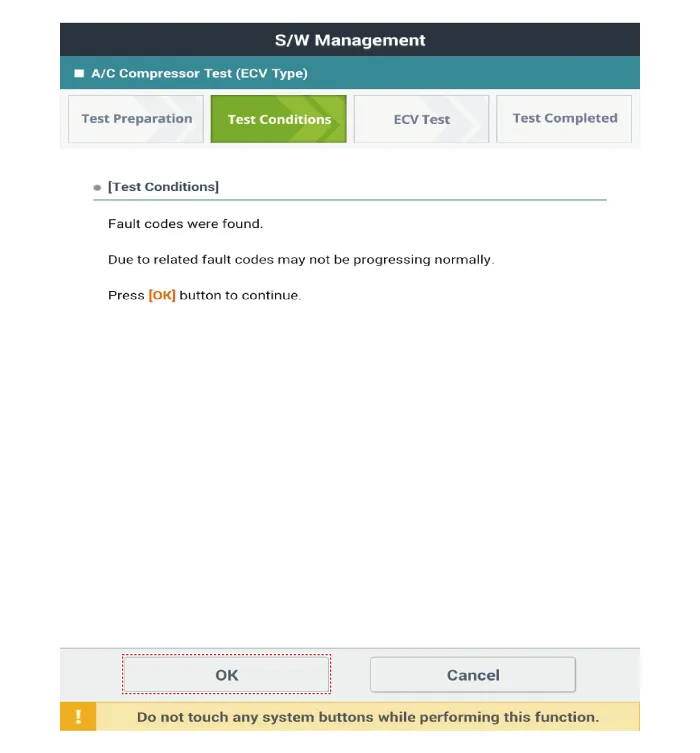

| 3. | Check if other DTC codes are found before inspect ECV compressor. If so, solve that problems first. If not, press 'OK' button to continue.

|

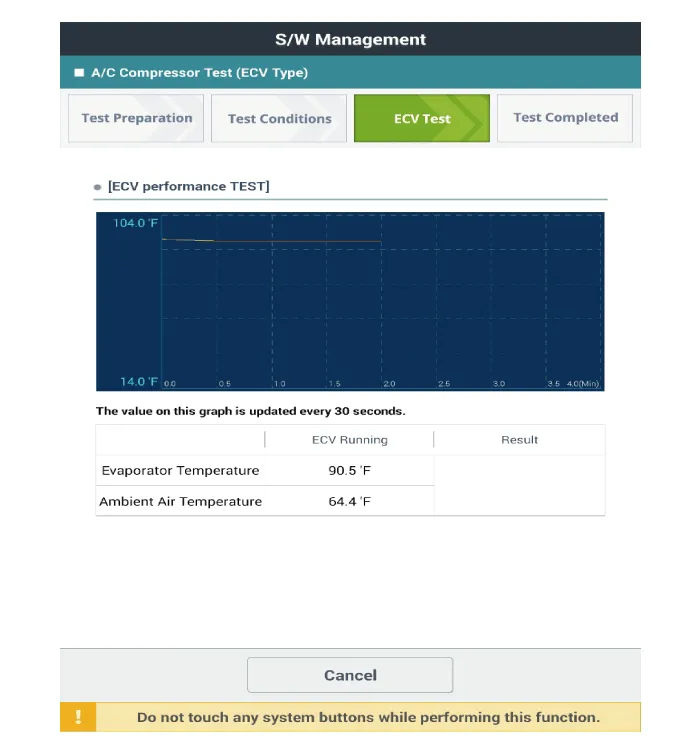

| 4. | Start inspection

|

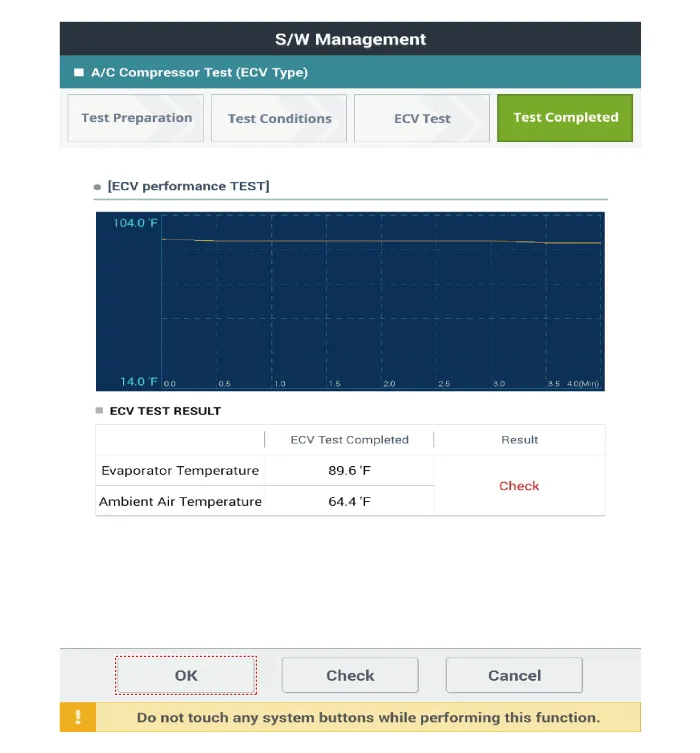

| 5. | Check the result of inspection. [ECV7]

[ECV8]

|

| 6. | If the result shows "Check" , click "Check" and follow the instruction.

|

| 7. | Inspect ECV again from the first step. |

| Disassembly |

| 1. | Remove the engine room under cover. (Refer to Engine Mechanical System - "Engine Room Cover") |

| 2. | Remove the front wheel guard. (Refer to Body - "Front Wheel Guard") |

| 3. | Loosen the drive belt. (Refer to Engine Mechanical System - "Drive Belt") |

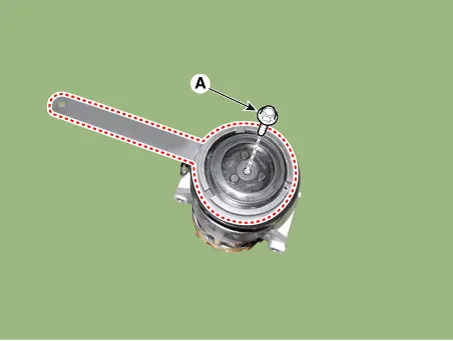

| 4. | Remove the clutch bolt (A) while holding the pulley with a clutch bolt remover (09977-3R000).

|

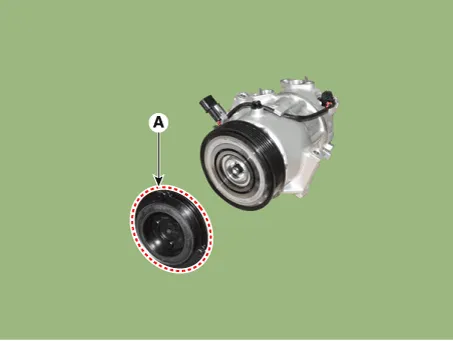

| 5. | Remove the disc & hub assembly (A).

|

| 6. | Remove the snap ring (A) with a snap ring plier.

|

| 7. | Remove the pulley (A).

|

| 8. | Reassemble in the reverse order of disassembly.

|

Components and components location Components Location1. Refrigerant Pipe Assembly Repair procedures Replacement1.If the compressor is marginally operable, run the engine at idle speed, and let the air conditioning work for a few minutes, then shut the engine off.

Components and components location Components Location[General type]1. Condenser[N Line]1. Condenser Repair procedures Inspection1.Check the condenser fins for clogging and damage.

Other information:

Hyundai Elantra (CN7) 2021-2026 Service Manual: Evaporator Core

Repair procedures Replacement1.Disconnect the negative (-) battery terminal. 2.Remove the heater and blower assembly.(Refer to Heater - "Heater Unit") 3.Remove the heater core cover (A) after loosening the mounting screws.4.Pull out the evaporator core (A) from the heater unit.

Hyundai Elantra (CN7) 2021-2026 Service Manual: Heater & A/C Control Unit (DATC)

Components and components location Components[This illustration shows the LHD type. RHD type is symmetrical.][Connector A] Pin No Function Pin No Function 1Battery9IGN22ILL+ (TAIL)10ISG Battery (+)3-11IGN14LIN BUS12HTD5-13-6-14-7-15-8RHEO (

Categories

- Manuals Home

- Hyundai Elantra Owners Manual

- Hyundai Elantra Service Manual

- Recommended Lubricants and Capacities

- Vehicle Information

- Auto Hold. Warning messages

- New on site

- Most important about car