Hyundai Elantra (CN7): Fuel Delivery System / High Pressure Fuel Pump

Repair procedures

| Removal |

|

| 1. | Release the residual pressure in fuel line. (Refer to Fuel Delivery System - "Release Residual Pressure in Fuel Line") |

| 2. | Turn the ignition switch OFF and disconnect the battery negative (-) cable.

|

| 3. | Remove the air cleaner assembly. (Refer to Engine Mechanical System - "Air Cleaner") |

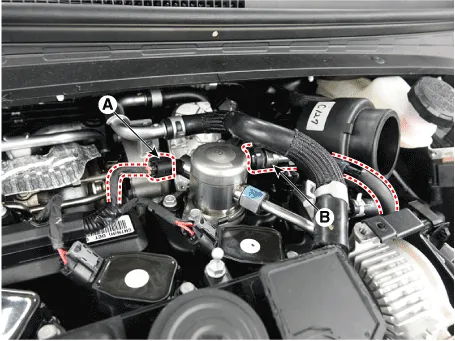

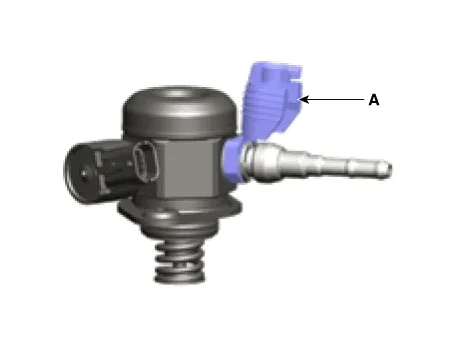

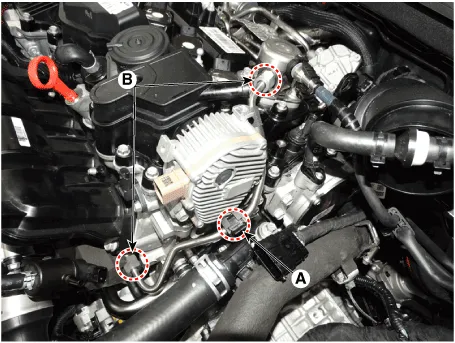

| 4. | Disconnect the fuel pressure control valve connector (A). |

| 5. | Disconnect the fuel feed tube quick-connector (B).

|

| 6. | Disconnect the engine wiring connector and harness clamps.

|

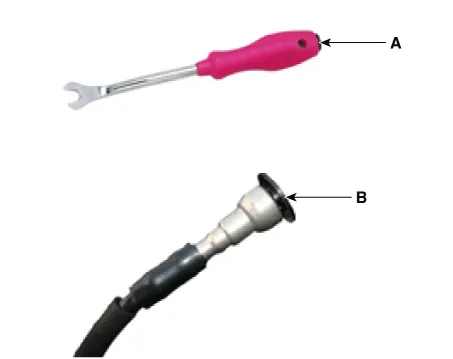

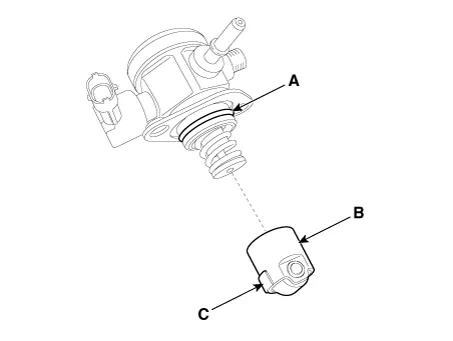

| 7. | Use the special service tool [SST No. : 09314-3Q100 or 09314-27130] to remove the high pressure fuel pipe function block mounting bolt (A) and removing the flange nut (B).

|

| 8. | Remove the mounting bolt (A) and remove the high pressure fuel pump from cylinder head assembly.

|

| Installation |

| 1. | Install in the reverse order of removal.

|

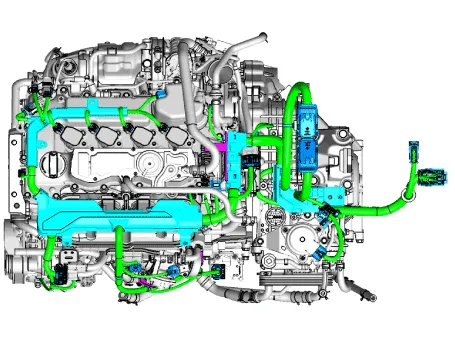

Repair procedures Removal • In case of removing the high pressure fuel pump, high pressure fuel pipe, delivery pipe, and injector, there may be injury caused by leakage of the high pressure fuel.

Other information:

Hyundai Elantra (CN7) 2021-2025 Service Manual: Antenna Coil

Repair procedures Removal1.Disconnect the negative (-) battery terminal.2.Remove the crash pad lower panel.(Refer to Body - "Crash Pad Lower Panel")3.Remove the steering column shroud panel.(Refer to Body - "Steering Column Shroud Panel")4.Disconnect the immobilizer connector (A) and press the locking pin (B) using an awl.

Hyundai Elantra (CN7) 2021-2025 Service Manual: Temperature Control Actuator

Description and operation DescriptionThe temperature control actuator is located at the heater unit. It regulates the temperature by the procedure as follows. The signal from the control unit adjusts the position of the temperature door by operating the temperature switch.

Categories

- Manuals Home

- Hyundai Elantra Owners Manual

- Hyundai Elantra Service Manual

- Driver assistance system

- Towing

- Maintenance

- New on site

- Most important about car