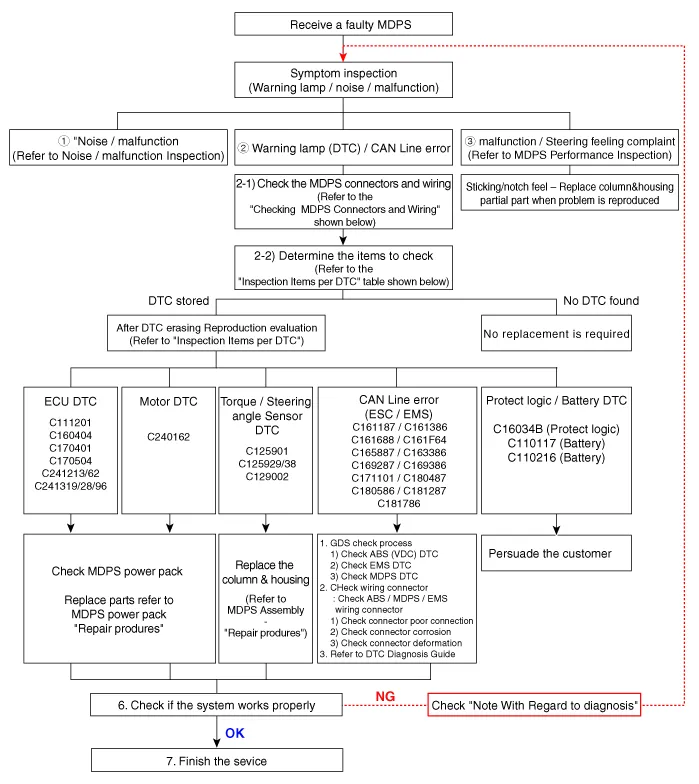

Hyundai Elantra (CN7): Motor Driven Power Steering / Repair procedures

| A/S Repair produres |

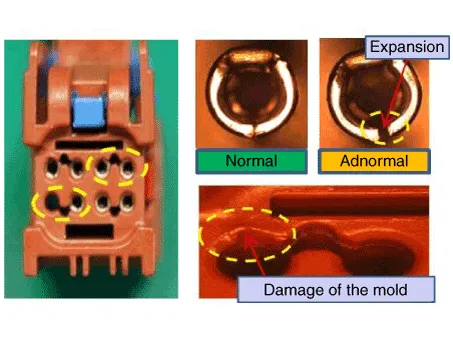

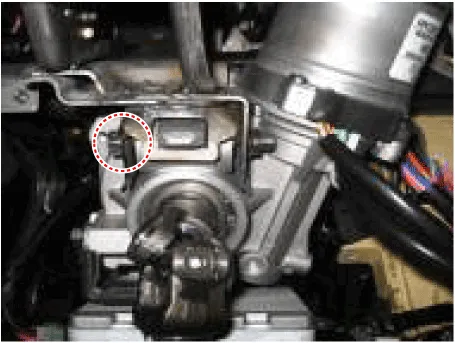

| 1. | Checking Connectors and Wiring. Check for damage, push-back, or improper connection in each connector and wiring.

|

| DTC | Problem | First analysis method | How to repair |

| C129002 | Torque sensor signal error | First erase DTC, | When the sensor connector flows, the warning lamp reoccurs Replace the sensor cable, and replace the column & housing (56390) |

| check connector connection | |||

| C125901 | Steering angle signal error | Earase DTC after resetting Steering angle zero point | |

| C125929 | check connector connection | ||

| C125938 | |||

| C111201 | Torque sensor power supply error | First erase DTC, check connector connection | When the sensor connector flows, the warning lamp reoccurs Replace the sensor cable, and replace the power pack (56370) |

| C160404 | ECU hardware error | Check after erasing the DTC | In case of reoccurrence, replace MDPS power pack (56370) |

| C170401 | Relay breaking of a wire | ||

| C170504 | ECU over/discharge error | ||

| C241216 | Motor circuit break / short | ||

| C241262 | Motor current error | ||

| C241319 | Over current error | ||

| C241328 | Motor electric current gate error | ||

| C241396 | Broken the motor current sensor | ||

| C240162 | Motor circuit error | ||

| C126154 | Steering angle zero point error | Check after resetting Steering angle zero point | Resetting Steering angle zero point or replace column & housing (56390) |

| Check sensor connector poor connect | |||

| C161187 | Not received the EMS CAN message | 1. Check chassis CAN condition | |

| C161F64 | Vehicle speed monitoring error | 2. Check connector connection | Earase DTC (No MDPS replacement) |

| C161F86 | Vehicle speed signal error | 3. Check engine ECU | |

| C161688 | CAN BUS OFF | 4. Start OFF history confirmation message while driving | |

| C162887 | Not received the cluster CAN signal | 2. Check cluster connector connection | |

| C163386 | Cluster display vehicle speed error | ||

| C169287 | Not received the VSM message | Check ESC, check chassis CAN condition | |

| C169386 | ESC signal error | ||

| C171101 | ECU abnormal end | Recheck after erasing the DTC | |

| C180487 | Cannot be received the LKA message | Check LKA, check CAN line | |

| C180586 | LKA signal error | ||

| C181287 | Not received the gateway CAN message | Check gateway | |

| C181786 | Gateway CAN signal error |

| 1. | Inspect steering angle and DTCs relevant to the steering system. |

| 2. | Inspection for heavy steering effort

|

| Case 1 | Case 2 | Case 3 |

|

|

|

| Multifunction switch noise | Clock spring noise | DAB / Wire noise |

| Retighten the bolt | Replace clock spring | Rearrange and replace DAB |

| Case 4 | Case 5 | Case 6 |

|

|

|

| Multifunction switch noise | MB nut mount defect | M10 nut mount defect |

| Replace multifunction switch | Retighten nut | Retighten nut |

| Case 7 | Case 8 |

|

|

| Cowl top bolt mount defect | Cowl bar nut mount defect |

| Retighten cowl top bolt | Replace clock spring |

Cautions to be taken when handling the MDPS (Motor Driven Power Steering)

|

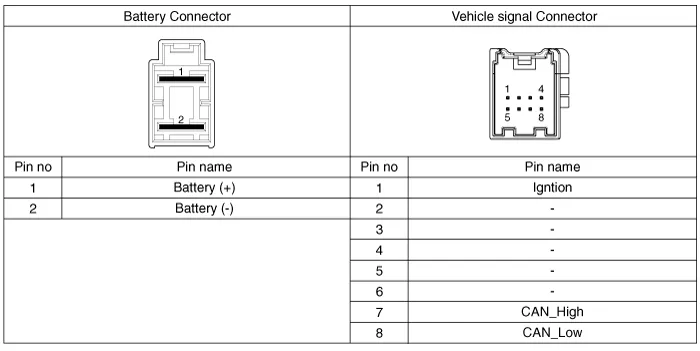

Schematic DiagramsC-MDPSTerminal function Type Pin No Description Battery1Battery +2Battery -VSS1IGN2-3-4-5-6-7HIGH CAN8LOW CAN

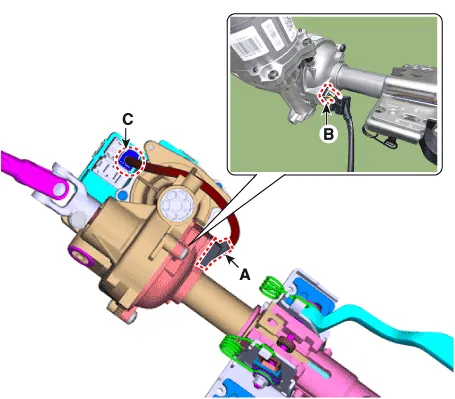

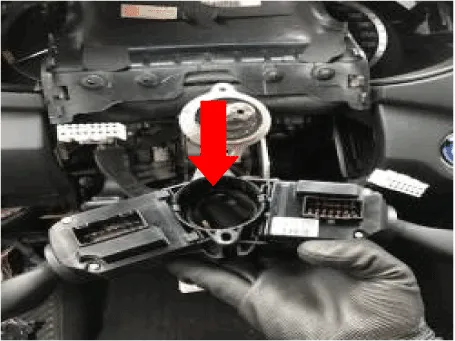

Repair procedures Replacement1.Turn the steering wheel so that the front wheels are placed in the straight ahead position. • If the steering wheel and the front tires are not set straight ahead together, it may affect the number of circulation of steering wheel and damage the cable inside the clock spring.

Other information:

Hyundai Elantra (CN7) 2021-2025 Service Manual: License Lamps

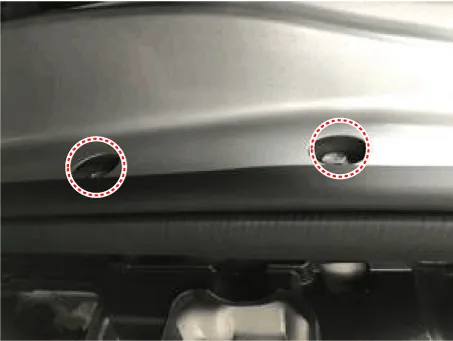

Repair procedures Removal1.Disconnect the negative (-) battery terminal.2.Push the lock pin (B) and remove the license lamp (A).3.Disconnect the license lamp connector (A).4.Replace the bulb (A).Installation1.Connect the license lamp connector.2.Install the license lamp.

Hyundai Elantra (CN7) 2021-2025 Service Manual: Description and operation

D

Categories

- Manuals Home

- Hyundai Elantra Owners Manual

- Hyundai Elantra Service Manual

- Components and components location

- Emergency situations

- Clutch System

- New on site

- Most important about car