Hyundai Elantra (CN7): Fuel Delivery System / Fuel Tank

Repair procedures

| Removal |

| 1. | Release the residual pressure in fuel line. (Refer to Fuel Delivery System - "Release Residual Pressure in Fuel Line") |

| 2. | Turn ignition switch OFF and disconnect the negative (-) battery cable. |

| 3. | Remove the rear seat. (Refer to Body - "Rear Seat Assembly") |

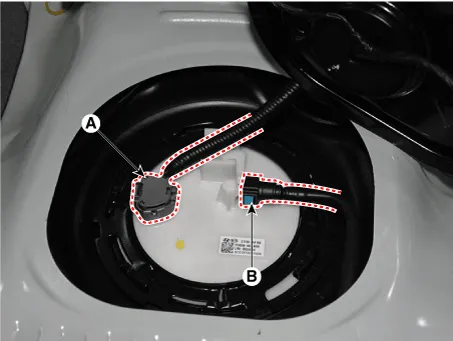

| 4. | Remove the fuel pump service cover (A).

|

| 5. | Disconnect the fuel pump connector (A). |

| 6. | Disconnect the fuel feed tube quick-connector (B).

|

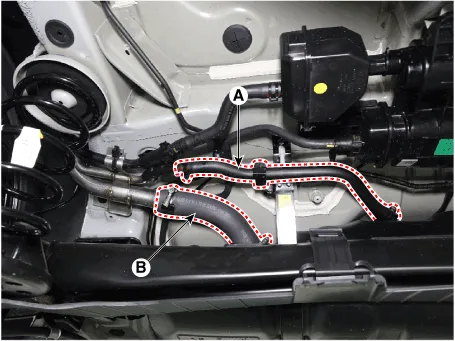

| 7. | Disconnect the leveling hose (A). |

| 8. | Disconnect the fuel filler hose (B).

|

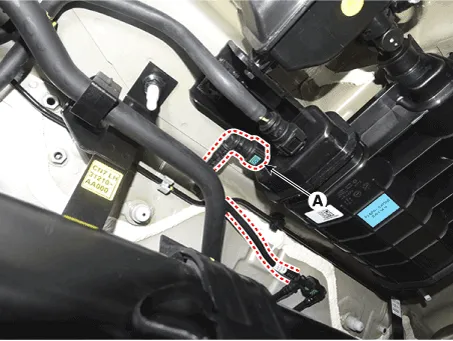

| 9. | Disconnect the vapor hose quick-connector (A)

|

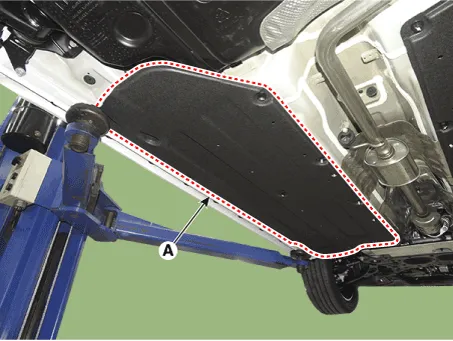

| 10. | Remove the floor under cover (A).

|

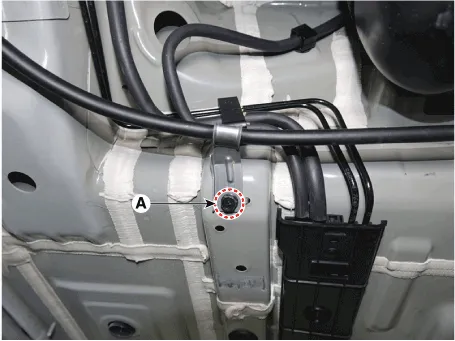

| 11. | Separate the brake line after removing the bracket mounting bolt (A).

|

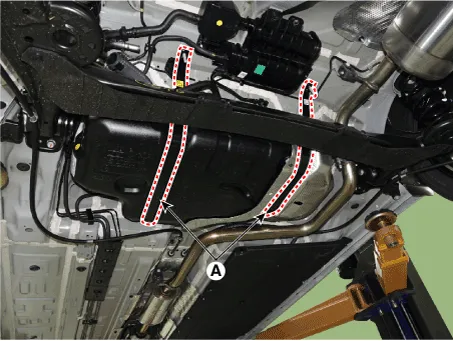

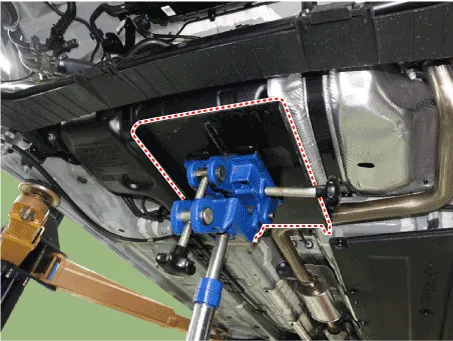

| 12. | Remove the fuel tank band (A).

|

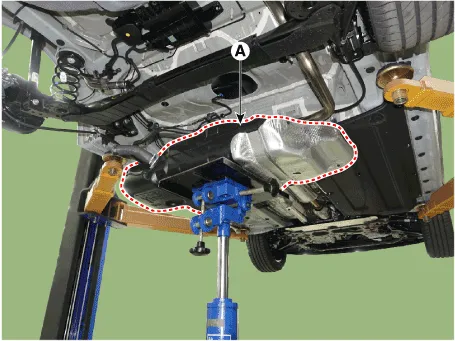

| 13. | Remove the fuel tank (A).

|

| Installation |

| 1. | Install in the reverse order of removal. |

Release Residual Pressure in Fuel Line • There may be some residual pressure even after "Release Residual Pressure in Fuel Line" work, so cover the hose connection with a shop towel to prevent residual fuel from spilling out before disconnecting any fuel connection.

Repair procedures Inspection[Fuel Pump]1.Turn ignition switch OFF and disconnect the negative (-) battery cable.2.Remove the fuel pump assembly.3.Check motor operation by fuel pump connector (A) connecting power (No.

Other information:

Hyundai Elantra (CN7) 2021-2026 Service Manual: Antenna Coil

Repair procedures Removal1.Disconnect the negative (-) battery terminal.2.Remove the crash pad lower panel.(Refer to Body - "Crash Pad Lower Panel")3.Remove the steering column shroud panel.(Refer to Body - "Steering Column Shroud Panel")4.Disconnect the immobilizer connector (A) and press the locking pin (B) using an awl.

Hyundai Elantra (CN7) 2021-2026 Service Manual: Parking Collision-Avoidance Assist (PCA)

Components and components location Components and Components Location Schematic diagrams Schematic DiagramsParking Collision-Avoidance Assist (PCA) Ultrasonic sensorParking Collision-Avoidance Assist (PCA) Rear view camera Repair procedures RemovalParking Collision-Avoidance Assist (PCA) Unit1.

Categories

- Manuals Home

- Hyundai Elantra Owners Manual

- Hyundai Elantra Service Manual

- General Tightening Torque Table. General information

- Integrated Thermal Management Module (ITM)

- Engine Mechanical System

- New on site

- Most important about car