Hyundai Elantra (CN7): Rear Suspension System / Rear torsion beam axle

Hyundai Elantra (CN7) 2021-2025 Service Manual / Suspension System / Rear Suspension System / Rear torsion beam axle

Components and components location

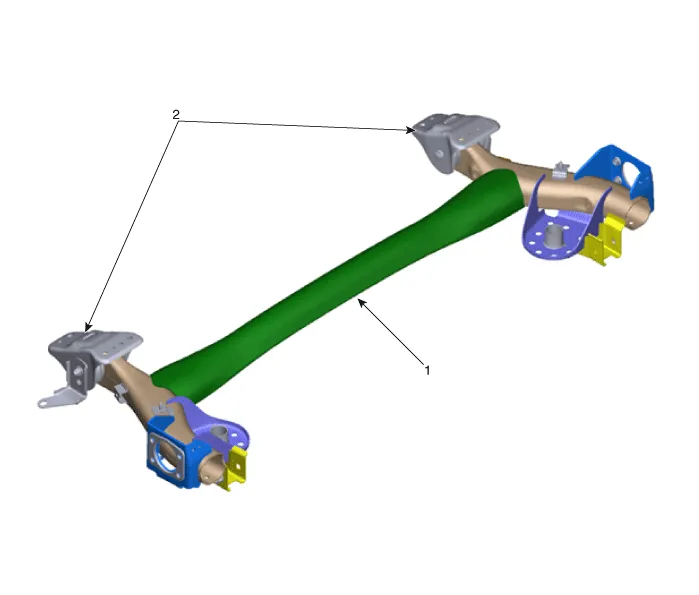

| Components |

| 1. Torsion beam axle | 2. Rear torsion beam chassis bracket |

Repair procedures

| Removal |

[Rear disc brake parking cable type]

| 1. | Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. |

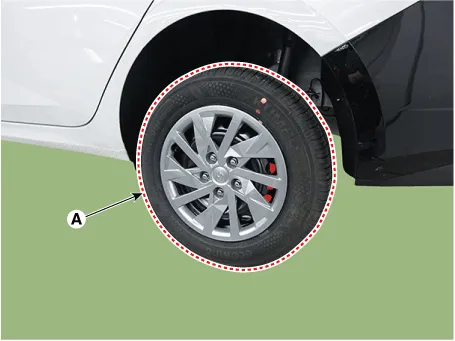

| 2. | Remove the rear wheel and tire (A) from the rear hub.

|

| 3. | Remove the rear caliper. (Refer to Brake System - "Rear Disc Brake") |

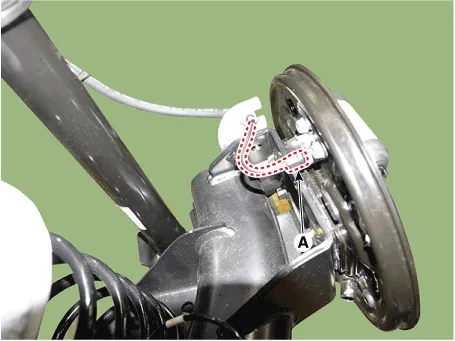

| 4. | Disconnect the rear wheel speed sensor connector (A).

|

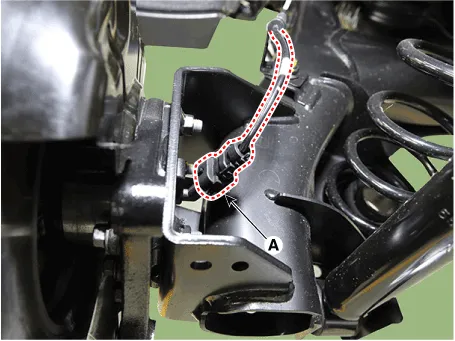

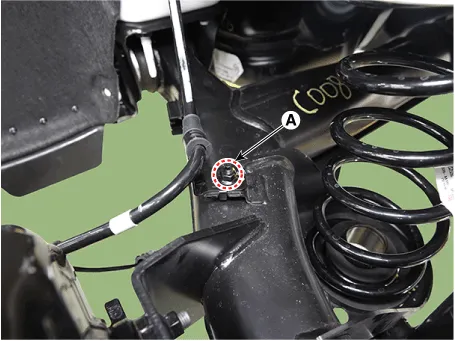

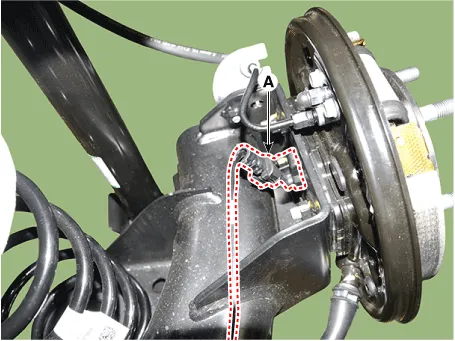

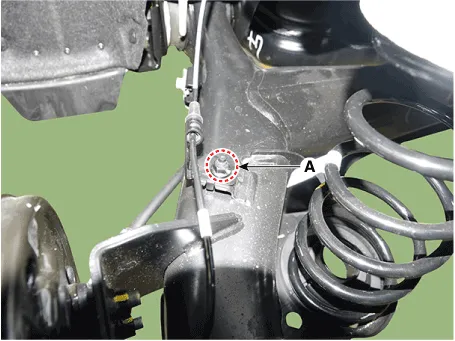

| 5. | Remove the rear wheel speed sensor bracket after loosening the mounting nut (A).

|

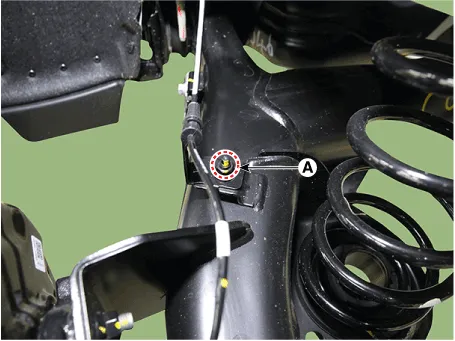

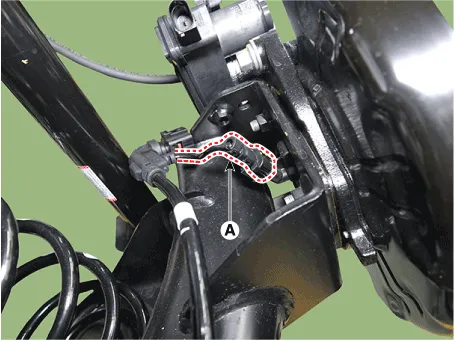

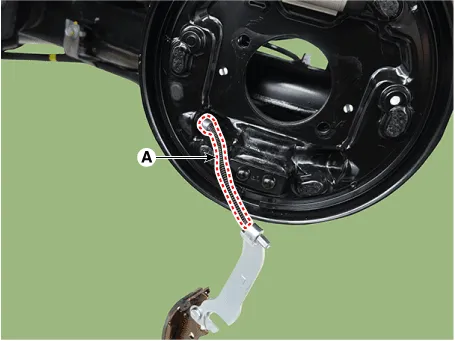

| 6. | Remove the parking brake cable bracket after loosening the mounting bolt (A).

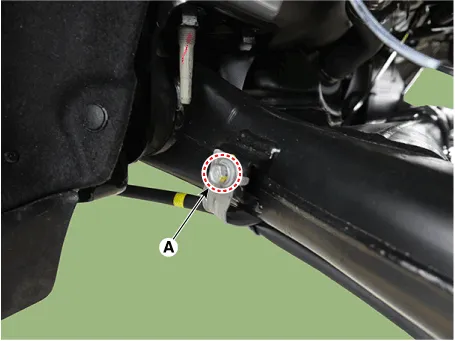

|

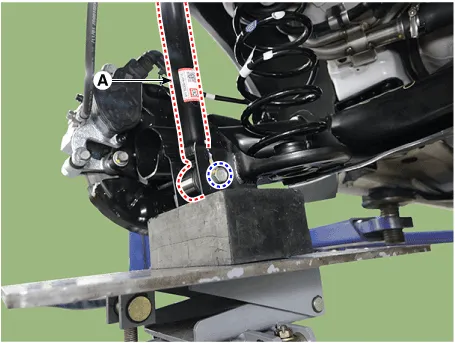

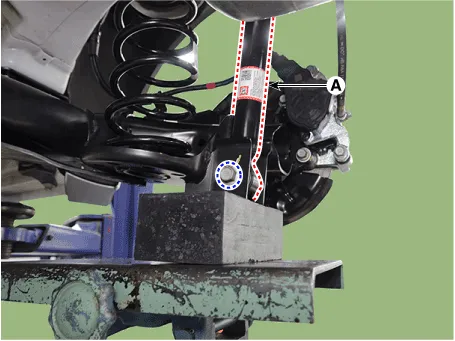

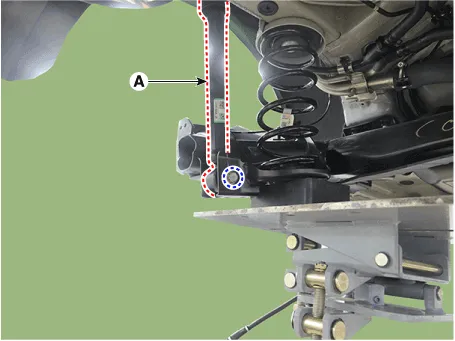

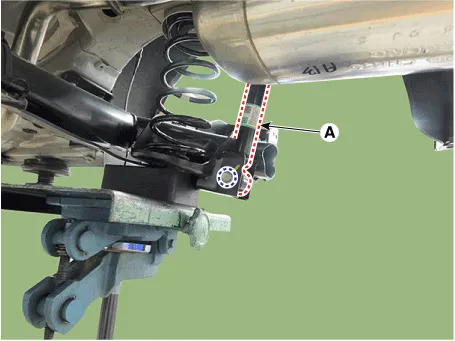

| 7. | Remove the rear shock absober (A) from the torsion beam axle after loosening the mounting bolt.

[LH]

[RH]

|

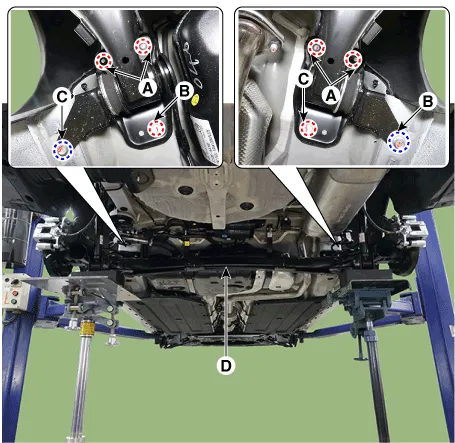

| 8. | Remove the torsion beam axle (D) after loosening the mounting nuts (A) and bolts (B, C).

|

[Rear disc brake EPB type]

| 1. | Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. |

| 2. | Remove the rear wheel and tire (A) from the rear hub.

|

| 3. | Remove the rear caliper. (Refer to Brake System - "Rear Disc Brake") |

| 4. | Disconnect the rear wheel speed sensor connector (A).

|

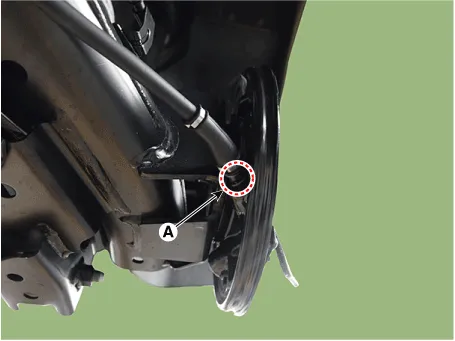

| 5. | Remove the rear wheel speed sensor bracket after loosening the mounting nut (A).

|

| 6. | Remove the rear shock absober (A) from the torsion beam axle after loosening the mounting bolt.

[LH]

[RH]

|

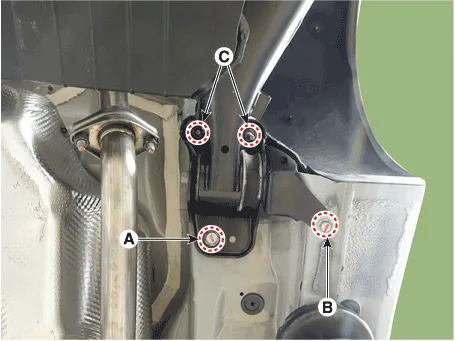

| 7. | Remove the torsion beam axle (D) after loosening the mounting nuts (A) and bolts (B, C).

|

[Rear drum brake type]

| 1. | Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. |

| 2. | Remove the rear wheel and tire (A) from the rear hub.

|

| 3. | Disconnect the rear wheel speed sensor connector (A).

|

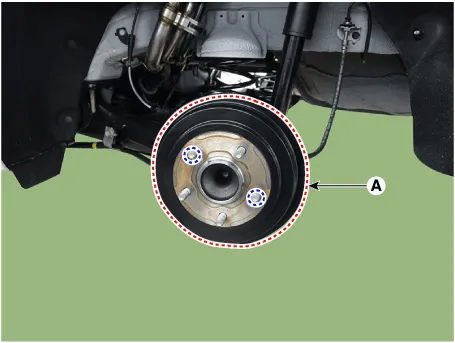

| 4. | Loosen the screw and then remove the rear drum brake (A).

|

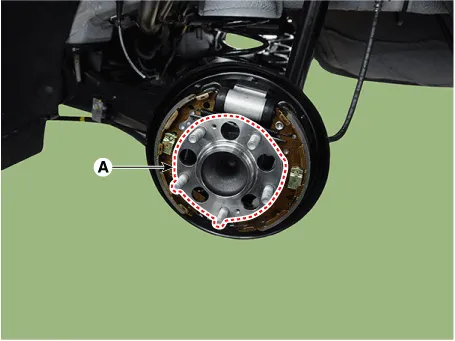

| 5. | Loosen the hub mounting bolts and then remove the hub (A) from the torsion beam.

|

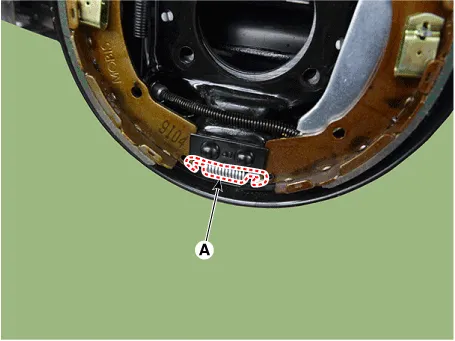

| 6. | Remove the lower shoe return spring (A).

|

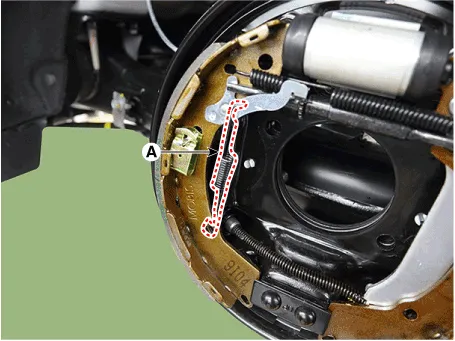

| 7. | Remove the adjuster spring (A).

|

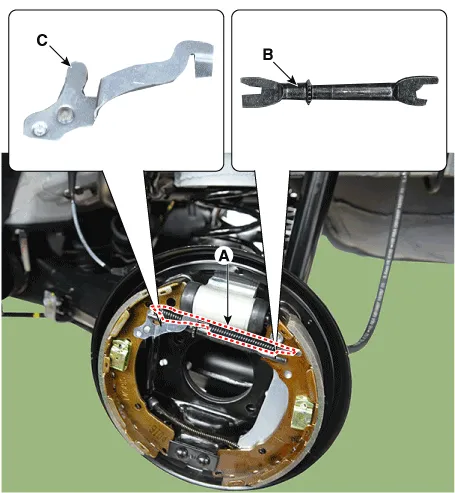

| 8. | Remove the upper shoe return spring (A). |

| 9. | Remove the upper shoe adjuster (B). |

| 10. | Remove the adjusting lever (C).

|

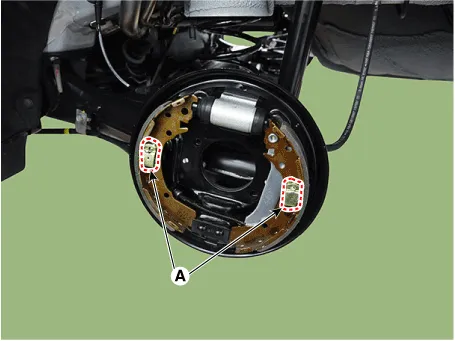

| 11. | Remove the shoe holder (A) and then remove the rining.

|

| 12. | Disconnect the parking brake cable (A) from lining.

|

| 13. | Remove the clip (A).

|

| 14. | Remove the brake hose (A) after loosening the brake flare nut.

|

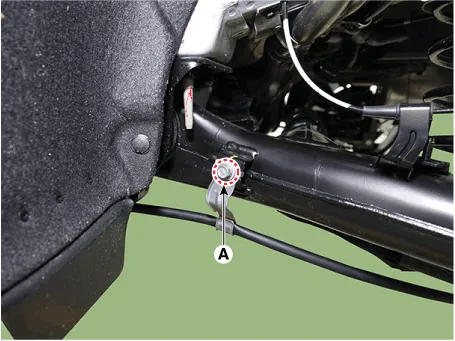

| 15. | Loosen the rear parking cable bracket mounting bolts (A).

|

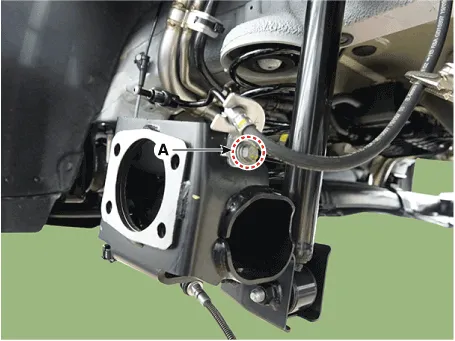

| 16. | Loosen the rear wheel speed sensor bracket mounting nuts (A).

|

| 17. | Remove the rear brake hose bracket mounting bolts (A).

|

| 18. | Support the rear torsion beam axle with a jack. |

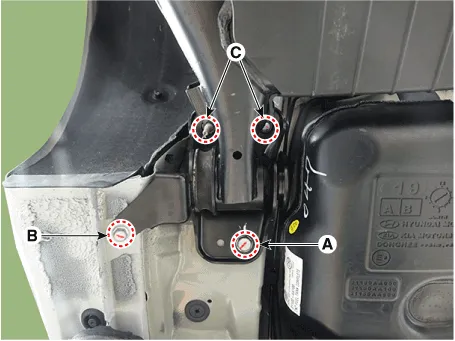

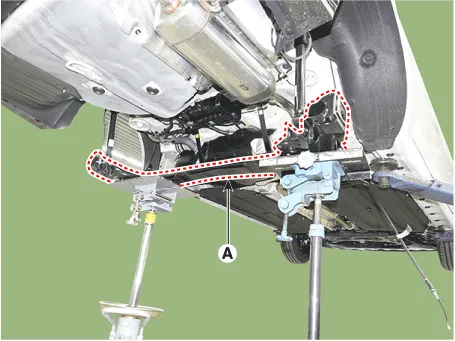

| 19. | Loosen the rear torsion beam axle stay mounting bolts (A, B) and nuts (C).

|

| 20. | Loosen the bolt and then separate the rear shock absorber (A) from the torsion beam axle.

|

| 21. | Remove the torsion beam axle (A).

|

| Replacement |

[Rear torsion beam axle bush replace]

| 1. | Remove the rear torsion beam axle from the vehicle. (Refer to Rear Torsion Beam Axle - "Removal") |

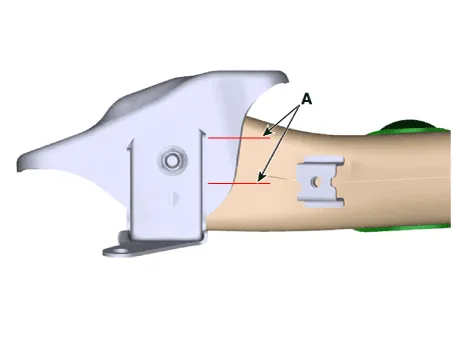

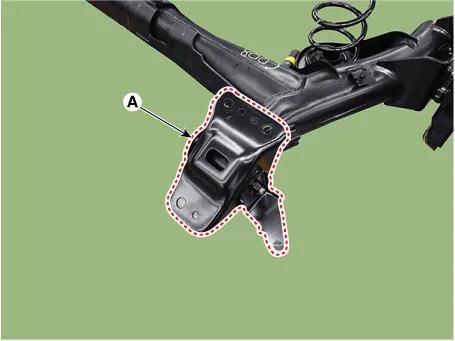

| 2. | Mark (A) between the rear torsional beam chassis bracket and the torsional beam axle.

|

| 3. | Remove the rear torsion beam axle stay (A) after loosening the mounting bolt and nut.

|

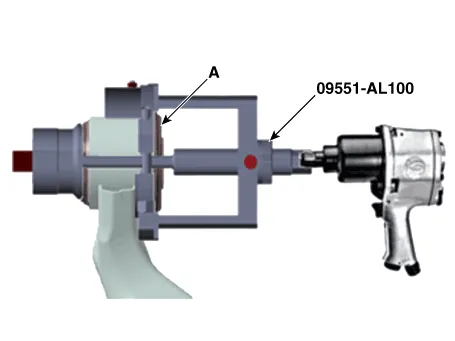

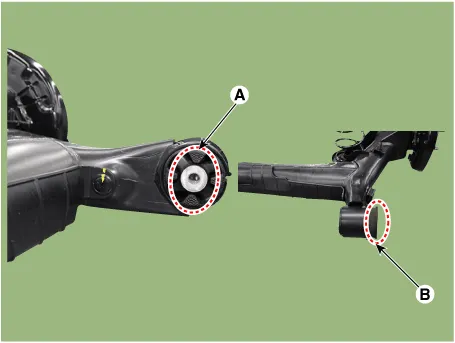

| 4. | Using the SST (09551-AL100), replace the bush (A).

|

| 5. | Install the torsion beam axle stay (A) and tighten the bolt and nut to the specified torque.

|

| Installation |

| 1. | To install, reverse the removal procedures. |

Components and components location Components1. Coil spring upper pad2. Rear coil spring3. Coil spring lower pad Repair procedures Removal1.

Other information:

Hyundai Elantra (CN7) 2021-2025 Service Manual: High Mounted Stop Lamp

Repair procedures Removal1.Disconnect the negative (-) battery terminal.2.Remove the rear package tray trim.(Refer to Body - "Rear Package Tray Trim")3.Loosen the mounting screws and remove the high mounted stop lamp (A).Installation1.Install the high mounted stop lamp.

Hyundai Elantra (CN7) 2021-2025 Service Manual: Ambient Temperature Sensor

Description and operation DescriptionThe ambient temperature sensor is located at the front of the condenser and detects ambient air temperature. It is a negative type thermistor; resistance will increase with lower temperature, and decrease with higher temperature.

Categories

- Manuals Home

- Hyundai Elantra Owners Manual

- Hyundai Elantra Service Manual

- Instrument Cluster

- Driver assistance system

- Integrated Thermal Management Module (ITM)

- New on site

- Most important about car

Copyright © 2025 www.helantra7.com - 0.0185