Hyundai Elantra (CN7): Front Suspension System / Sub Frame

Repair procedures

| Removal |

| 1. | Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. |

| 2. | Remove the front wheel and tire (A) from the front hub.

|

| 3. | Remove stabilizer bar link from the front strut after loosening the mounting nut.

|

| 4. | Remove the tie rod end ball joint by using the special service tool.

|

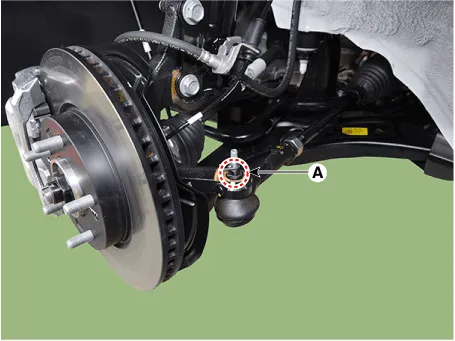

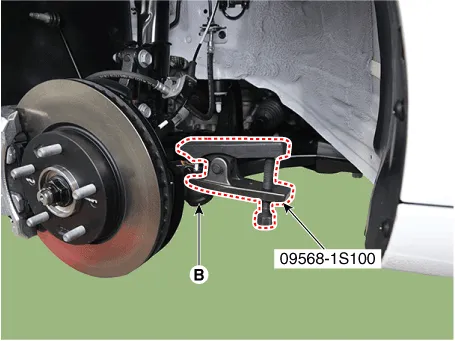

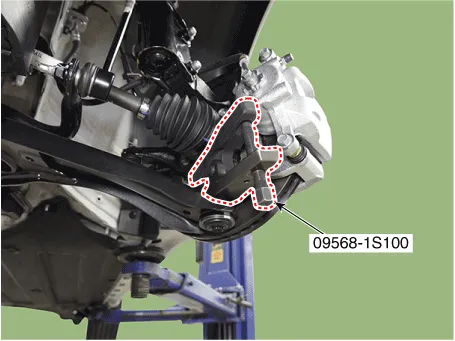

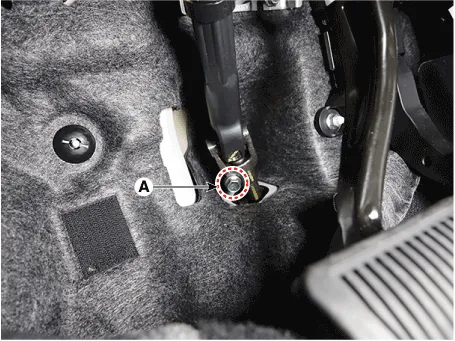

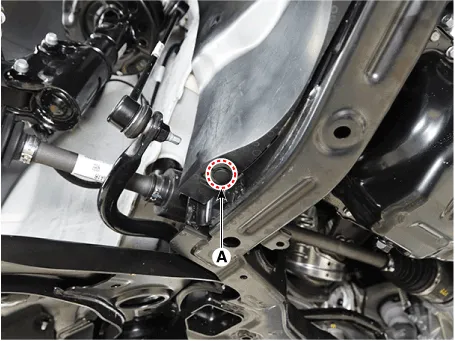

| 5. | Separate the lower arm ball joint by using the SST (09568-1S100) after loosening the lower arm mounting nut (A).

|

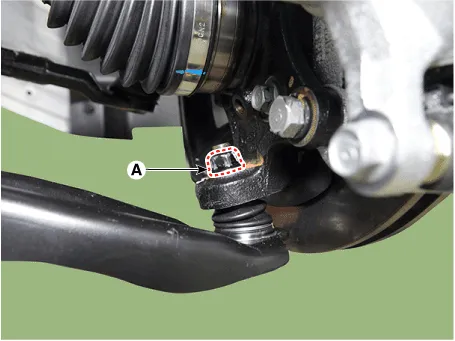

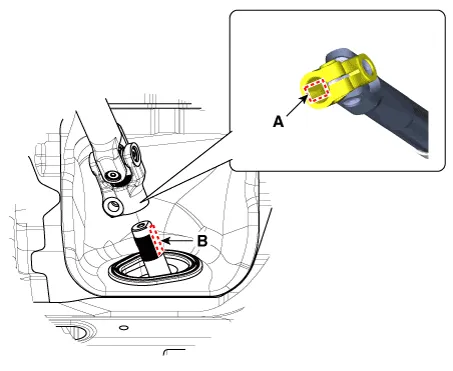

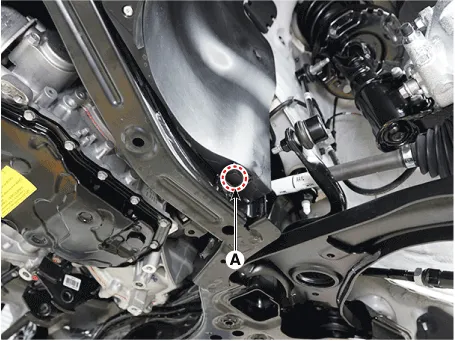

| 6. | Separate the universal joint from the steering gear box after loosening the universal joint mounting bolt (A).

|

| 7. | Remove the engine room under cover. (Refer to Engine Mechanical System - "Engine Room Under Cover") |

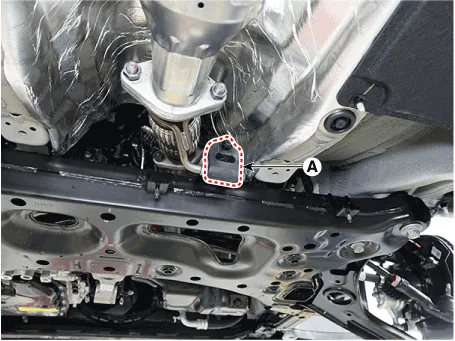

| 8. | Remove the muffler rubber hanger (A).

|

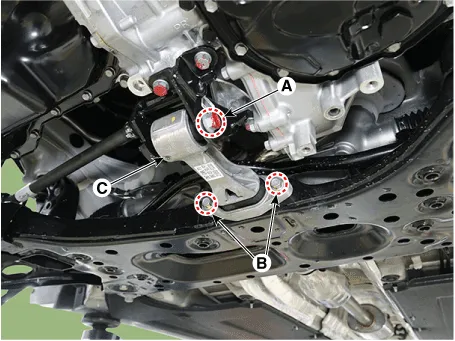

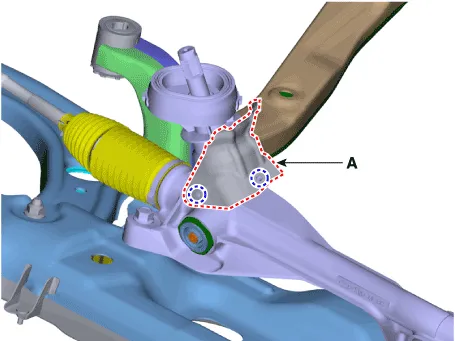

| 9. | Remove the roll rod bracket (C) after loosening the mounting bolts (A, B).

|

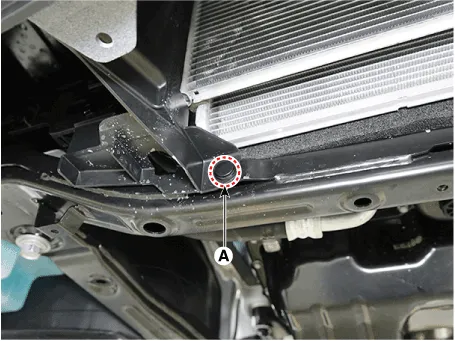

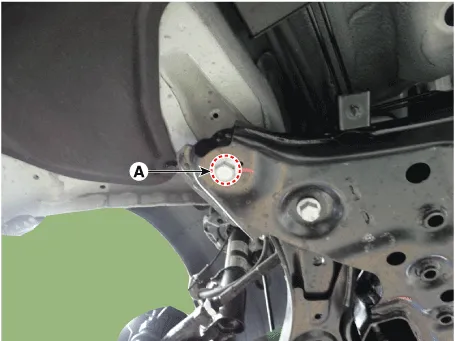

| 10. | Remove the fastener (A). [LH]

[RH]

|

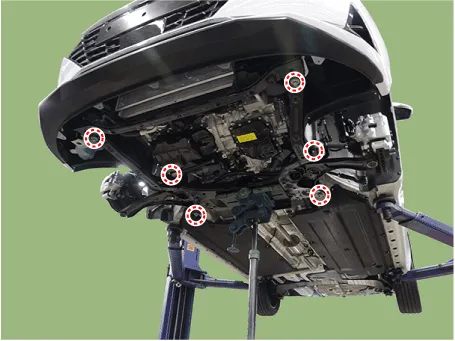

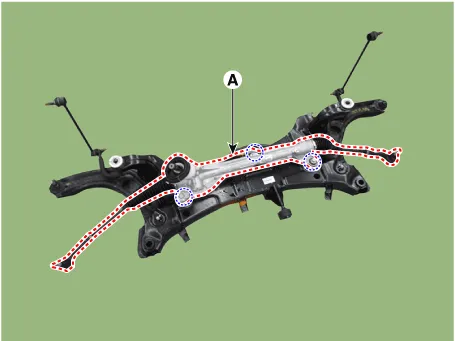

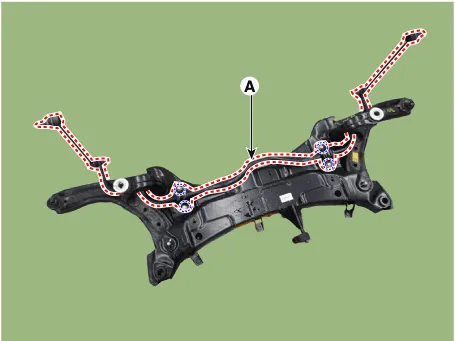

| 11. | Remove the sub frame after loosening the mounting bolts and nuts.

|

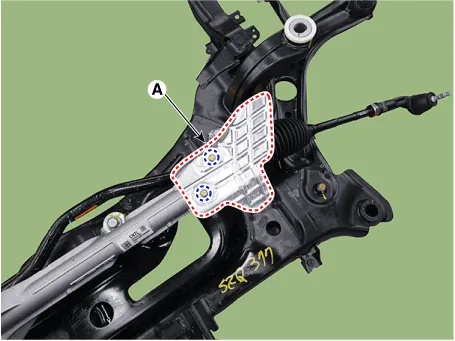

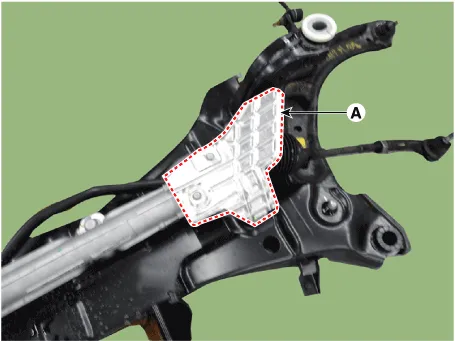

| 12. | Remove the heat protector (A).

|

| 13. | Remove the steering gear box (A) from the sub frame after loosening the mounting bolts.

|

| 14. | Remove the stabilizer bar (A) from the sub frame after loosening the mounting bolts.

|

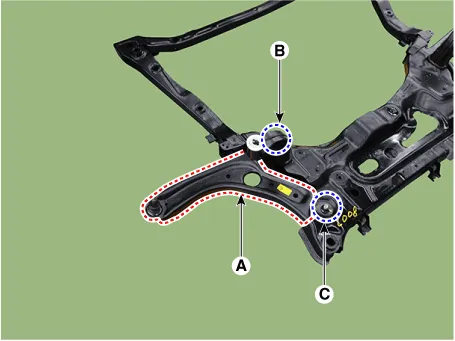

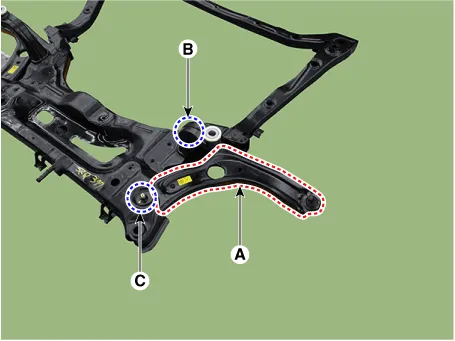

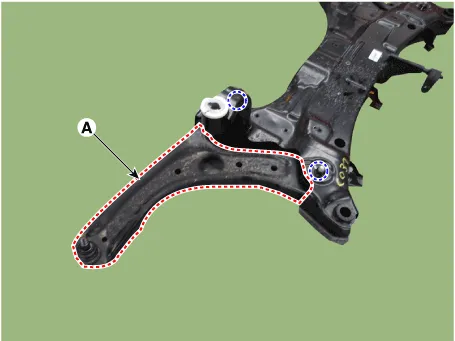

| 15. | Remove the front lower arm (A) from the sub frame.

[LH]

[RH]

|

| 1. | Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. |

| 2. | Remove the front wheel and tire (A) from the front hub.

|

| 3. | Remove stabilizer bar link from the front strut after loosening the mounting nut.

|

| 4. | Remove the tie rod end ball joint by using the special service tool.

|

| 5. | Separate the lower arm ball joint by using the SST (09568-1S100) after loosening the lower arm mounting nut (A).

|

| 6. | Separate the universal joint from the steering gear box after loosening the universal joint mounting bolt.

|

| 7. | Remove the engine room under cover. (Refer to Engine Mechanical System - "Engine Room Under Cover") |

| 8. | Remove the muffler rubber hanger (A).

|

| 9. | Remove the roll rod bracket (C) after loosening the mounting bolts (A, B).

|

| 10. | Remove the subframe by loosening the mounting bolts (A) and nuts (B).

|

| 11. | Remove the heat protector (A).

|

| 12. | Remove the steering gear box (A) after loosening the mounting bolts.

|

| 13. | Remove the stabilizer bar (A) after loosening the mounting bolts.

|

| 14. | Remove the front lower arm (A) from the sub frame.

[LH]

[RH]

|

| Installation |

| 1. | To install, reverse the removal procedures. |

| 2. | Check the alignment. (Refer to Suspension System - "Alingment") |

Repair procedures Removal1.Loosen the wheel nuts slightly.Raise the vehicle, and make sure it is securely supported.2.Remove the front wheel and tire (A) from the front hub.

Other information:

Hyundai Elantra (CN7) 2021-2025 Service Manual: Antenna Coil

Repair procedures Removal1.Disconnect the negative (-) battery terminal.2.Remove the crash pad lower panel.(Refer to Body - "Crash Pad Lower Panel")3.Remove the steering column shroud panel.(Refer to Body - "Steering Column Shroud Panel")4.Disconnect the immobilizer connector (A) and press the locking pin (B) using an awl.

Hyundai Elantra (CN7) 2021-2025 Service Manual: Blower Unit

Components and components location Component Location1. Blower unit assemblyComponents1. Blower unit assebmly2. Blower upper cover [LH]3. Duct seal4. Blower upper cover [RH]5. Intake actuator6. Air filter cover7. Intake door8. Air filter9. Blower upper case10.

Categories

- Manuals Home

- Hyundai Elantra Owners Manual

- Hyundai Elantra Service Manual

- Drive Mode

- Rear Seats

- Towing

- New on site

- Most important about car